How to protect wood from moisture. How to properly treat wood from moisture and decay. Wood processing by folk methods

Record dated: 7-31-2016

Wood is a versatile and budget material, which, with proper processing, is able to please us with its qualities for many years. In today's publication, I will touch on the topic of wood impregnation, as well as talk about ways to protect wooden buildings in the country or in a country house. I will show a video in which experienced people will share with us their best practices in the field of tree protection from adverse factors.

Please note that according to engineers, a treated wood surface can last two to three times longer than an untreated one. I’ll tell you about everything in more detail later, the material will be of interest to everyone, even women. I write without specific terms, simply and accessible to everyone.

What are the ways to protect wooden buildings

To begin with, the tree does not like direct contact with moisture, that is, any wooden structure must be protected from water. For example, a roofed wooden shed will last much longer than a wooden compost bin. Just for the reason that the box and the rains are watered, and from the inside it is in contact with raw materials.

Therefore, the design of structures must necessarily take into account these features of the tree. All buildings are protected by canopies, roofs. The material itself - wood, must be dry during construction, otherwise it may begin to rot immediately after construction.

Special attention should be paid to the ventilation of a wooden building. Under the floor, ideally, the wind should walk, then the logs will not rot, they will always be dry, even in a cloudy long autumn. In our dacha, under our houses, air circulates freely, the floor is dry, the roof has large ledges. We spied on the inhabitants of Asia, where it rains for six months, that the roof extension should be larger. And it's really, really helpful. You can also open the window, and the rain will not pour into the window.

The second point is the treatment of wood with impregnations with antiseptics, to protect against fire, etc. Plus, coating the outside with a protective layer of varnish or paint. Together, these measures will increase the service life of wooden products many times over. A simple example from life - in my parents' private house, one side of the fence facing the street was processed in accordance with all the rules and painted, and the other part, facing the backyard, was left without any processing.

As a result, after five years, the untreated part was already pretty worn out - traces of the beginning of decay became visible, a fungus appeared, and lichen began to sprout. It was our mistake, we wanted to save on processing, as a result, the fence quickly deteriorated ... If you process your fence, then do everything according to the instructions, do not save on protective equipment.

What wood to choose for construction

According to experts, the best building material is pine. Because it combines the qualities of strength and ease of processing. Suitable for construction, the price is optimal. Spruce somewhat falls short of pine, but also quite a consumable material. If something is made of wood, then try to take exactly pine. At the same time, do not forget about antiseptic impregnations.

In terms of durability and strength, the best wood is oak and larch. Decks of open terraces are made from oak and larch boards, paths are paved. However, for the price of such building materials will cost much more. And sometimes it will be more profitable to use brick, cement, tile than this wood.

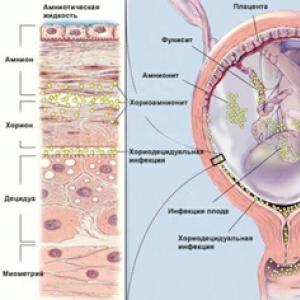

Please note that the greatest damage to wooden structures is caused by bacteria and other microorganisms that inhabit a damp wooden structure. Where there is no way to remove moisture, the tree will rot much more quickly precisely because of the multiplication of bacterial flora. Decay itself is the result of the activity of these organisms. Accordingly, either we do not allow the tree to come into contact with water, or we impregnate it with antiseptics and paint it.

The easiest way to protect a wooden surface is to treat it with drying oil. This video clip shows in detail how to apply drying oil on a wooden surface, what types of drying oils are.

Pay attention to this simple and proven way of processing wood. The author of the video introduces the material in great detail, I would even say too detailed. But this is probably a plus, but not a minus. It is important to know all the subtleties in order to get the best result for sure.

What impregnation to choose for wood

The primary treatment of wooden structures with impregnations should be carried out at an early stage, ideally even at the stage of material preparation. That is, all boards and all timber must be processed while they are in a pile. So they planned the scope of work for the next day, took the required amount of material and impregnated it in the evening in order to build it the next day. And even better - immediately process everything in advance, so that later you will not be distracted.

At first, my husband went the other way, that is, he began to process our extension after the frame was made, as a result, it was simply impossible to physically process some parts of the frame with solutions. They were left without food. I don't know how this affected their durability.

There are a lot of disinfectant wood solutions, and you have to choose according to your needs. We like Senezh and Aquatex, the neighbor prefers Wood Healer. All products on the market are working, and it's all about personal choice. Someone buys more expensive, foreign firms Tikkurila and Pinotex, but our budget is still not so big.

If long-term protection is important to you, then the use of preservative formulations is optimal. The name speaks for itself, these liquids essentially preserve the tree for centuries. Protect against mold, bacteria, fungi, and also prevent fire - pyroprotection. Pay attention to the composition of KSD and Bio-sept.

Having processed a wooden surface once, do not think that it is forever, over time, the properties of the impregnations are lost and it is necessary to re-treat the wood. In each case, check the instructions for your composition. Do not forget to regularly carry out preventive treatment with antiseptics, then your wooden structure will last a very long time.

Rules for applying preparations to wood material

Antiseptic impregnations should be applied to the cleaned wood. All resins protruding from the wood must be removed, and the skin should also be cleaned of the tree. Scrap off the mold either manually or with a metal brush - a nozzle for a drill or grinder.

Impregnation is applied twice, with the interval necessary for the first layer to dry. This technique allows you to get a deeper penetration of the protective composition into the treated surface. When working with antiseptics, protect your hands and organs of vision and breathing - work in rubber gloves, goggles and a mask.

Overview video on wood impregnations

Well, that's all I have for today! Study the materials, draw conclusions, and proceed to protect your wooden structures from all adverse factors. As I said, now there is such a wide choice of everything that you can spend all the time studying the proposals of manufacturers, but there will be no time to build. The prospect is not the best, that's why I'm trying for you. Successes in construction and repair!

Natural wood is, of course, the leader among materials for building a house. The absolute environmental friendliness of wood, high aesthetics and simply unlimited possibilities of use - all this reveals the secret of the popularity of the material for many centuries. However, wood is not without its drawbacks. First of all, this is a weak level of resistance to negative external factors. That is why the question of how to treat wood and boards from decay is extremely important for all connoisseurs of natural and natural.

How to treat wood and boards from decay

The processes of biological destruction of wood, or rotting, is a rather unpleasant process, which, unfortunately, is inherent in this material. The processes of decay begin to occur and accelerate:

- At high air humidity;

- At high humidity of the feedstock;

- When there is no good ventilation;

- With temperature fluctuations;

- When condensation accumulates;

- During the freezing of the material;

- Frequent contact with damp soil.

It is best to apply preventive measures even during the harvesting and storage of wood.

During storage, the moisture content of wood decreases, so it is advisable to use a tree that has lain felled. Previously, this technique was used: they cut down a tree in the winter in order to start construction in the summer. Currently, there is no need to withstand such a long period. Technological measures are used to protect wood.

Wood decay treatment involves protecting the wood from moisture penetrating through the pores. This can be done with a good waterproofing layer, from the moisture contained in the atmosphere - by painting with special paint and a good roof. High-quality thermal insulation and a vapor barrier coating, pre-equipped ventilation will protect against condensates.

In addition, it is necessary to place the wooden structure of the building much higher than the ground level. In addition, the ends of the log house walls should be sheathed with boards and treated with a special tool. But first things first.

In order for a wooden product to please you for many years with aesthetic characteristics and a reliable design, experts advise preventive processing of the material at the manufacturing stage.

Means for treating wood from decay

Modern methods of combating decay processes involve processing with special means:

- The ends can be processed with Senezh TOR;

- The walls can be covered with a special Senezh NEO product, which will protect it from moisture penetration;

- It is also possible to apply a finishing layer of finishing like Senezh Akvadecor.

Attention. Recently, negative reviews about Senezh products have become more frequent. When choosing funds, consult several points of sale.

All these methods in their complex combination will help protect the wood from decay. It is up to you to decide which impregnation against wood decay is better to choose, you need to be based on the type of wood and its operating conditions.

End processing Senezh TOR video:

Fire retardant wood treatment

Wood, unfortunately, is a very combustible material. You can protect it from fire by using special means. They are best combined with the treatment of wood with an antiseptic. The best conditions for wood impregnation are:

- Low moisture content of wood (up to 25%);

- The temperature of the impregnation itself is about 60-85 ° C;

- Application of impregnation on specially made tattoos.

Previously, buildings in the private sector were not treated for fire. Currently, such preventive treatment is practiced. In such cases, it is possible to cover the surface with special refractory materials, often a simple impregnation with saline solutions is used. In the second case, when fire hits the surface, the salt begins to melt and creates a film that can stop the fire.

Fire fighting equipment is divided into:

- Passive ones create a film on the surface of the tree. A good protection against fire is impregnation with compounds formed on the basis of sulfates and phosphates of ammonium, boric acid and borax. The advantages of borax and boric acid are that they have an additional antiseptic effect. When fire hits the surface, the salt begins to melt, creating a film that can stop the fire.

- Active agents not only block the access of oxygen. BUT and contribute to a decrease in temperature, emit non-combustible gases, prevent the release of resins and combustible gases.

You can prepare a wood impregnation agent at home according to the recipe given in the video.

Means for protecting wood from fires, or fire retardants, can be:

- Senezh OGNEBIO;

- Neomid 450;

- Pirilax;

- Valty Pokhyusti.

Processing is carried out by means of the above means in several layers.

- Antiseptic

- Conservation

Both methods involve the use of special chemicals. Antiseptic means applying a special substance - antiseptic manually, with a brush or roller. And conservation - only in the factory by soaking raw materials in special baths, as well as autoclaving.

There are several types of antiseptics. Their use is mandatory in cases where mold has already begun to appear. They are:

- Water soluble. Completely eco-friendly, do not have an unpleasant odor and dry quickly. Ideal for wall, floor, ceiling, window and door surfaces. It is not recommended to use them for a tree that has constant contact with water.

- Water repellent. They have a rather sharp odor, but a deeper level of penetration. Excellent for use in baths, saunas, basements and cellars.

- Flying basis. They cover the wood with a thick film that takes a long time to dry. Perfectly are suitable both for interior, and for front processing.

- Oil based. They are water insoluble and also form a strong film. They can only be used to impregnate dry wood. Not recommended for residential areas.

- on a combined basis. Great for any kind of wood. They have not only antiseptic, but also fire and bioprotective properties.

Specific means

The following remedies are excellent for protecting wood from mold:

- "Wood Doctor" Suitable for all types of wood, regardless of the level of damage. Non-toxic and completely safe.

- "Bioks" - belongs to the class of protective-textural coatings. It protects the wood from mold, and is also able to emphasize the texture of the wood. It can be both colored and transparent.

- "Biosept" - is considered one of the best means. It can be used both inside and outside. It is based on new generation biocides. The tool is absolutely environmentally friendly, reliable and safe.

- "Aquatex" is great for planed and sawn surfaces (for example, doors, poitus, platbands and much more).

- "Pinotex" is also great for almost any type of wood, does not fade and provides excellent protection.

- "Elkon" there are several varieties that differ in their characteristics. It is applied outside and in rooms. It is used for drawing on freshly processed material.

- Carticide compound. You can get acquainted with its characteristics by watching the video.

Recommendations for choosing means for treating wood from decay

Before choosing an impregnation in the store, depending on the operating conditions of the wood, pay attention to the following characteristics:

- Duration of impregnation on wood.

- Is it possible to use this impregnation in rooms with temperature changes.

Does the impregnation cause corrosion of the metal. This quality must be taken into account if further connection with metal fasteners is expected.

How deeply the impregnation penetrates into the wood. Is it suitable for rooms with high humidity.

How environmentally friendly is the impregnation? Is it possible to use it inside residential premises or places where animals live.

Is the impregnation designed to counteract the appearance of fungus.

Does not emit an unpleasant odor from the treated surface during temperature changes or high humidity.

These questions can be asked to a representative of the trading organization. All information is available in the instructions attached to the materials.

Coating rules

In order to apply a protective coating, special knowledge and skills are not required. You can do this work on your own. Before starting work, pay attention to the following characteristics:

- Stock up on protective equipment such as a mask, gloves and goggles.

- In the process, you will need the following tools: a brush, a metal brush, detergents, sandpaper and a scraper.

- Before starting work, inspect the wood itself. Cracks on its surface indicate the need for processing.

- The optimal time for work is considered to be a temperature of 20-25 0 C. It is allowed to start work at 10 0 C, and not higher than 40 0 C. It is strictly forbidden to work out a frozen tree.

If the wood has previously been treated or coated, all traces on the surface must be cleaned and removed.

Perform preparatory work and processing in the following sequence:

- Clean the wood of dirt and old coatings with a solvent or scraper.

- Treat the surface with sandpaper and remove dirt with a detergent solution.

- Create conditions for the wood to dry completely.

- When applying protective agents, pay special attention to end surfaces, joints, cuts.

- In the case of applying a second layer of work, perform at least three hours later.

It will take at least 48 hours for the coating to dry completely. The time may vary depending on the temperature, humidity in the room.

Processing a log house with an antiseptic video

Folk methods of wood protection

There are also folk methods for protecting wood without chemistry from fires. This is the preparation of a solution based on clay, salt and water. The proportion of its preparation is as follows:

- Clay - 75 parts;

- Salt - 5 parts;

- Water - 20 parts.

All this mixture is diluted to a thick mass and applied in several layers. Also among folk remedies, a coating prepared on the basis of superphosphates is popular. The mixture is made according to the ratio of water and superphosphate 25 to 75. It is applied in a similar way in two or three layers.

Important: such a coating tends to harden after 5-6 hours, so the prepared composition must be used during this period, otherwise it will become unusable.

The problem of how to treat wood and boards from decay has been of interest to people for a long time. And over the years, many folk methods have accumulated to protect wood from biodegradation. So, what to do with the tree so that it does not rot:

Conclusion

Protective equipment is selected individually. Processing of terraces, arbors, rafters and rough floors is carried out using hard-to-remove solutions. If there is very high humidity in the premises, then products with an ultra-reliable level of protection are used. You should also consider:

- room temperature;

- Operating conditions;

- Validity period of funds;

- Exterior finish.

You need to choose the means and methods based on your own needs and preferences.

We also recommend you:

The tree is widely used in construction and everyday life. This durable material retains its decorative effect until mold and other pests appear. To prevent damage, the surface is treated with various compositions of natural, industrial origin.

Why does mold appear on wood

Mushrooms are the main enemy of wood. Conditions conducive to their appearance:

- High .

- Stagnant air without ventilation.

- Sudden changes in temperature, the formation of condensation on the surface of products.

- Freezing of damp wood, which leads to deep penetration of spores.

- It is located on the bark of a tree, does not develop during its lifetime.

- Appears when products come into contact with the ground.

- Comes from the air.

Pre-protection to reduce the risk of infection:

There are several varieties:

- Black mold has many strains that are impossible to distinguish with the naked eye. General characteristics - excessive activity, the ability to quickly destroy, damage the material.

It poses a serious danger to humans: spores, if they enter the respiratory tract, cause allergic reactions, irritation, and poisoning. The variety is resistant to the influences used to combat it.

- White mold is less resistant to aggressive agents. It affects wooden objects, products, food. Colonial whiteness for humans does not pose a serious danger, but can cause allergies.

- Blue fungus infects wood, leading to its decay. Dangerous for load-bearing structures: during decay, their ability to withstand loads and maintain rigidity is reduced.

- Actinomycetes are a cross between fungi and algae. They prefer to appear in conditions of high humidity, soften the wood structure.

Fighting methods

There are many methods, natural and synthetic means.

Folk remedies

Folk methods against wood damage are gentle, effective, but protect the material for a short time.

Medium 1: resin

Resin heated before application helps against fungal spores.

- efficient,

- safe

- cheap.

- The surface remains sticky.

- The resin is viscous, difficult to apply, you need to stretch.

Remedy 2: silicate glue

Silicate glue diluted to a state of medium viscosity is used. They process the surfaces of wooden products, coatings 1-2 times.

It is a safe hypoallergenic composition. Has a short-term effect, not suitable for some types of mold.

Remedy 3: potassium bichromate, sulfuric acid

5% potassium bichromate solution, 5% sulfuric acid concentrate are mixed in equal proportions.

The resulting solution processes the boards adjacent to the soil structures. The method is effective, but dangerous for the soil.

Remedy 4: Vinegar and Baking Soda

To get rid of an already existing focus, the place is sprinkled with soda, sprinkled with 9 or 6% acetic acid.

Remedy 5: salt, acid, boiling water

A solution is prepared from 5 liters of hot boiled water, 1 kg of sodium chloride, 50 g of boric acid. Thoroughly mix, process the tree.

Remedy 6: copper sulfate

Take 100 g of dry matter, diluted in 10 liters of water. The boards are treated with a solution, then they are dried, used for construction.

Medium 7: white

Chlorine bleach cleans the fungus well, but keep in mind that the liquid brightens the wood.

In baths, saunas, it is possible to remove mushrooms only with folk remedies. To cure the affected area, clean the boards with soda, pour vinegar, wait for the reaction to end. Then the reagents are washed off with water, the area is covered with tea tree oil diluted in warm water.

Folk remedies are not always effective and safe. They are used when there are no special preparations at hand, and the problem needs to be solved quickly.

Modern compositions

Preparations are divided into 3 groups according to the method of application and action:

- paints with a opaque or translucent effect;

Paints, varnishes perform 2 functions: help remove mold, participate in the finish. They create a water-repellent coating that protects the tree for a long time.

Treatment with antiseptics is the main way to fight. It can be superficial, deep:

- Surface treatment of boards is carried out in the house during construction or repair. Sometimes lumber suppliers provide lumber already processed in this way.

- Deep impregnation by conservation method allows you to remove all spores from the surface of the product and to the depth. Penetration of chemical compounds occurs under autoclave conditions with temperature changes.

Varieties of antiseptics

Synthetic agents against tree fungus are distinguished by composition, effect of action:

To prevent the appearance, get rid of the fungus in the house, it is necessary to choose the right composition of the antiseptic or protective coating. It is worth considering:

- room humidity;

- the presence of contact with the ground;

- air temperature;

- operating conditions of the product, surface.

The home climate is well tolerated by soluble or water-repellent solutions; in dry rooms, paintwork can be limited. For the street, you should choose more rigid means.

Carrying out work

The appearance of fungus on a tree can be prevented. Another option is to remove existing mold.

Pre-protection

To create a protective layer on a new product, during production or before construction, a wooden object is coated with varnishes, paints, antiseptics. Application is carried out on a dry, clean surface. Waiting for drying. If necessary, repeat the operation. Apply:

- tassels,

- rollers,

- sprayers.

wood treatment

To destroy the existing fungus, it is not necessary to dismantle the product. If the mold has not grown, has not had time to spoil the structure of the wood, it is enough to carry out a complex of medical works:

- Clean the affected area with a spatula, brush. When doing this, be sure to wear gloves.

- Re-prime the surface with deep penetration compounds or impregnate it with an antiseptic.

- Apply top coat.

After using synthetic agents, the lesion does not resume. As a rule, chemicals kill all pests present on the surface of the tree.

All photos from the article

Wood is one of the most common building materials, of which gazebos, fences, benches, verandas, etc. are often made in suburban areas. In order for all these products to last for many years, it is necessary to periodically treat wood with protective compounds from all kinds of negative factors. In this article, we will take a closer look at how and with what to properly process a tree with our own hands.

General information

The durability of wood products is negatively affected by a number of factors:

If you do not protect the tree from these negative factors, then very quickly the product will become unusable. Therefore, processing is a mandatory procedure, and the durability of a wooden structure directly depends on the quality of its implementation.

In the photo - an example of an untreated rotten tree

This procedure is usually carried out in two stages:

Below we will take a closer look at each of these stages.

Impregnation

purpose

When deciding how to process a wooden gazebo on the street, a bench or other structure, first of all, you need to choose an antiseptic impregnation.

True, modern compounds, as a rule, have a complex effect, and they are not only antiseptics, but also flame retardants that protect wood from fire. In addition, impregnations often contain oil or wax, which prevents moisture from penetrating into the wood structure. Some of them are decorative and can be used instead of paintwork.

Antiseptic primers serve as an alternative to impregnations. In fact, they have the same effect on wood as impregnations, but in addition they improve the adhesion of the paintwork to the wood.

Impregnation treatment

The process of impregnation on wood is as follows:

- Before processing a wooden fence on the street or any other structure, you first need to prepare the surface. Namely, remove the old coating, as well as clean it from dirt and dust.

- Then the surface must be sanded with fine sandpaper., which will allow the impregnation to be better absorbed.

- After that, you can proceed directly to the application of the composition. You can cover the surface with a primer with a brush or paint roller. Some types of impregnations are rubbed with soft swabs.

- After drying, the composition is applied to the surface again.

This completes the wood impregnation process.

Paintwork

Types of coatings

Most impregnations are not able to provide complete protection for wood, so an additional surface is needed. Currently, there is a huge range of various paint and varnish coatings on the market.

Their choice depends on such points as:

- Appearance of the product;

- Durability of the protective layer;

- Environmental friendliness;

- The drying rate of the treated surface, etc.

Below we will take a closer look at the most common types of compounds and their main properties:

| Paint type | Peculiarities |

| Water dispersion paint | Recently, these types of paints are very popular, due to their following positive qualities:

As a rule, these coatings form an attractive matt surface while maintaining the wood grain. As for the shortcomings, they include only a fairly high price. |

| Unlike the previous composition, it forms a bright glossy film on the surface. It should be noted that alkyd enamels are resistant not only to atmospheric, but also to mechanical influences. In addition, they dry quickly and do not turn yellow under the influence of the sun. The only thing to consider is that alkyd enamels and paints emit a strong toxic odor. True, after drying, it disappears. |

|

| Polyurethane enamel | It has good resistance to abrasion and mechanical stress. Therefore, choosing how to process a wooden bench on the street or even the floor on the veranda, you can give preference to polyurethane enamel. It will reliably protect the surface for several years, despite a variety of negative environmental influences. True, it should be borne in mind that the cost of polyurethane enamels is quite high. Therefore, it is not always advisable to use them. |

| Oil paint | Not so long ago, this type of coating was the most common, however, in recent years, the popularity of oil paints has declined sharply. This is due to the appearance on the market of better materials. The fact is that oil paints quickly begin to peel and turn yellow in the sun, and besides, they are quite toxic. Their only advantage is their low cost. |

| Polyurethane varnish | It is one of the most common transparent coatings. Polyurethane varnish resists various negative atmospheric influences well, besides, it “lays down” perfectly and dries quickly. |

| Water based varnish | It also has good performance, however, it dries for a long time. Therefore, it can not be used in all cases. |

| As you might guess from the name, it is used for processing yachts. This coating is the most reliable and durable among varnishes. True, the cost of such compositions is quite high. |

Advice!

When choosing how to process a wooden porch on the street, you should consider the design of the house and the surrounding exterior.

If, for example, the house is finished with clapboard, then the best solution would be to open the porch with polyurethane or yacht varnish.

Painting

In order for the paintwork to reliably protect the tree, it is necessary not only to choose the right type of wood, but also to paint it correctly.

Instructions for surface treatment with varnish or paint are as follows:

- The first step is to eliminate all existing defects on the surface of the wood.- chips, cracks, etc. For this you need. After that, the treated areas need to be sanded.

- Next, you need to prepare the paintwork- shake the liquid thoroughly, if the paint is tinted, then you need to add the required amount of dye to get the desired color or shade.

- The coating is then applied to the surface. For paint, you can use a brush, paint roller or even a special sprayer. Lacquer is usually applied with a brush or a soft swab.

The coating must be applied in a uniform thin layer. The tool must first be carefully wrung out to prevent drips.

After the first layer has dried, the paintwork is applied a second time. As a rule, two layers are enough to get a quality surface.

Advice!

After work, the tool must immediately be thoroughly washed so that it can be used in the next wood processing.

This completes the woodworking process.

Conclusion

Wood processing is an extremely responsible procedure, on which the appearance of wooden structures and their durability depend. For reliable protection, the treatment must be complex using impregnation and paintwork.

You can find additional information on the topic voiced from the video in this article.

All photos from the article

With all its undeniable advantages, wood has one significant drawback - poor resistance to decay and pests, especially if the operating conditions are not the most favorable. Of course, there are some breeds that are immune to moisture, but there are not many of them, and the cost of such options is much higher, so the processing of boards from decay is a relevant and important issue, and our article will be devoted to it.

What factors should be considered when choosing a particular option

If you do not know how to process the material, then when determining the solution, you need to be guided by several criteria:

| Operating conditions | Naturally, all elements located inside buildings are exposed to adverse effects much less than a board used in outdoor structures. It should also be noted that inside the buildings there are rooms with an unfavorable microclimate (for example, a bathroom and a kitchen), which also require additional processing. |

| Material condition | For example, a heat-treated decking board does not need special protection, and as for ordinary materials, without additional work they will very quickly become unusable, and it is unlikely that they will be able to be restored, and damaged structures will have to be changed. |

| Node Location | Everything is simple here: if the board is visible, then a colorless composition or options that create an attractive coating are most often used. If the elements are hidden or located in the ground, then there is no talk of external beauty, the most important thing is to ensure the reliability of protection and preserve the properties of the composition after processing for the longest possible time. |

| Features of the situation | At this point, various factors are taken into account: from financial possibilities, because the price of compositions is often rather big, and large structures require significant volumes, the method of application is also important, because even when doing work with your own hands, you can use a brush, roller or spray gun |

Important! If the processing of elements is difficult or impossible, then it is best to purchase a material that has undergone special processes in the factory and has increased resistance to adverse effects.