Do-it-yourself roof: step-by-step instructions for installing various types of roofs. Tips for installing the roof of a house with your own hands Step-by-step construction of the roof

According to statistics, every second homeowner built his home on his own. According to their reviews, self-erecting a roof is one of the most difficult stages for non-professional builders. Therefore, it is very important to approach this stage, having in mind a complete understanding of all the nuances of the process. To figure out how to make a roof with your own hands, you need to study the device, installation technology, the procedure for work and the features of fastening all components of the structure.

Roof types

First you need to decide on the form. To date, the most popular types are:

Form FeaturesCovering the roof with one single slope will save nerves and materials, since structurally this is the simplest option. If you make such a frame yourself, then the labor intensity of the work will be the least, and the installation speed will be high. But this form has a drawback - there is no possibility of arranging a full-fledged attic or attic, since the under-roof space is too low.

A gable roof is mounted much more often. It is a little more difficult to manufacture, but allows you to get more space. Compared to the four-slope, it has less complexity and mass, but it will be necessary to make triangular gables along the ends of the building.

Gable - the most popular form

Gable - the most popular form Before proceeding with the independent construction of a roof with four slopes, you will need to seriously prepare. Such a system has more elements than the previous two. In addition, there is no way to make full-fledged windows in the attic, since the roof structure is devoid of gables and installation is difficult or unavoidable.

The four-slope is difficult to construct, but savings are achieved due to the absence of gables

The four-slope is difficult to construct, but savings are achieved due to the absence of gables For an attic, a combined design with. In this case, the lower part of the roof has a greater slope than the upper part. This assembly allows you to raise the ceiling in the room and make the house built more comfortable.

A broken line is not the most “architectural”, but very efficient in terms of space used

A broken line is not the most “architectural”, but very efficient in terms of space used Calculation

Before starting work, you need to make a design calculation. It makes no sense to calculate sections of all elements. In most cases, they can be accepted constructively:

- mauerlat - 150x150 mm;

- racks - 100x150 or 100x100 mm, depending on the section of the rafters;

- struts - 100x150 or 50x150 mm, taking into account the convenience of connecting with rafters;

- puffs - 50x150 mm on both sides;

- runs - 100x150 or 150x50 mm;

- pads with a thickness of 32 to 50 mm.

The calculation is usually performed only for rafter and sloping legs. It is required to choose the height and width of the section. The parameters depend on:

- roofing material;

- snow region;

- the pitch of the rafters (selected so that it is convenient to lay the insulation, for mineral wool between the elements, 58 cm should remain in the light);

- span.

You can choose the cross section of the rafters using general recommendations. But in this case, it is recommended to make a small margin.

The calculation is usually performed for rafter legs

The calculation is usually performed for rafter legs If you do not want to delve into the intricacies of calculations, you can use special ones.

If you intend to make a warm roof, then the height of the section of the legs is selected taking into account the thickness of the insulation. It must be mounted so that it does not protrude above the supporting beams. You also need to take into account that for mineral wool a ventilation gap of 2-4 cm is made between it and the coating. If the height of the rafters is not enough for this, the installation of a counter-lattice (counter-rail) is provided.

Step-by-step instructions for performing work

The sequence of stages of the construction of the roof is as follows:

- taking measurements of the building box (the dimensions may slightly differ from the design ones);

- preparation of materials and tools, wood treatment with an antiseptic;

- fastening the Mauerlat to the wall;

- installation of a ridge crossbar, if needed (for layered rafters);

- frame installation;

- strengthening the roof with the help of racks, struts and puffs;

- waterproofing;

- crate;

- provision of ventilation;

- installation of drips;

- cover installation.

Fixing the Mauerlat

In order for the roof to be securely fixed, care must be taken to securely connect it to the wall of the building. If a wooden house is being built, then the Mauerlat is not required - the upper crown of a bar or log acts as this element. In this case, fastening to the wall is carried out using special “floating” fasteners. They are sold ready-made, most often they are called sleds. This version of the roof device allows the entire structure to slightly shift when the walls shrink without damage and deformation.

"Sliding" mount in a wooden house

"Sliding" mount in a wooden house

A similar situation arises with a frame house. In this case, the upper wall trim will be the Mauerlat. It is attached to the racks of the frame with a gash using corners, staples or nails.

Methods for attaching rafters to the strapping in a frame house

Methods for attaching rafters to the strapping in a frame house The construction of a roof made of brick, concrete blocks or concrete implies fastening through a Mauerlat. In this case, there are several ways.

There are four ways to put the Mauerlat on the wall:

- on staples;

- on studs;

- for anchor bolts.

Mauerlat can be fixed on brackets. In this case, wooden blocks are laid in the masonry from the inside. They should be located at a distance of 4 rows from the edge. One side of the bracket is attached to the Mauerlat, and the other to the same bar in the masonry. The method can also be classified as simple. It is not recommended for large buildings with high loads.

Mauerlat fastening on brackets. In the laying of the wall, antiseptic wooden bars are provided with a step of 1-1.5 m

Mauerlat fastening on brackets. In the laying of the wall, antiseptic wooden bars are provided with a step of 1-1.5 m Do-it-yourself fastening during roof installation can be carried out through studs or anchor bolts with a diameter of 10-12 mm. Fasteners are laid in the masonry. A Mauerlat is temporarily placed on the edge, you need to lightly hit it with a hammer. After that, recesses remain on the beam in the places of fasteners. On them you need to make holes for the studs. After that, the timber is put on the fasteners and the nuts are tightened. The method is ideal for walls made of lightweight concrete in the presence of a monolithic armo-belt.

Fastening rafters to Mauerlat

In houses made of brick or stone, it is more reasonable to carry out with the help of a rigid attachment of the rafters to the Mauerlat. In this case, you can use both layered and hanging systems. The design assumes two ways:

- with a notch;

- without notch.

In the first case, the rafters are hemmed with a slope so that they are tightly adjacent to the Mauerlat. For the removal of the cornice, fillies are provided. They are attached to the leg with an overlap of at least 1 m. Rigid fixation of the knot should be done using self-tapping screws, nails or staples. But the assembled frame will have greater reliability if metal corners with holes for self-tapping screws are used for fixing.

The method without cutting often does not involve the use of fillies. In this case, the frame overhang is provided by the beams themselves. This option is simpler than the previous one, since it does not require high accuracy. It is suitable for beginners. For a snug fit to the Mauerlat, in this case, use persistent bars or boards. Rigid fixation, as in the previous case, is performed with metal corners on both sides.

Fastening rafters to the wall

The frame made must be fixed to the box of the building - this will not allow a strong gust of wind to tear off the roof. To do this, it is necessary to take as a rule the use of a twist of two wires with a diameter of 4 mm. They are wrapped around the leg at the place of support on the Mauerlat, and after that the wire is attached to the wall on an anchor or ruff about 4-5 rows before the cut. The element must be laid in advance in masonry.

Windbreak protection

Windbreak protection For a wooden house, you can simplify the task. You can assemble the frame using staples. This option will speed up the process. But it is important to remember that this method is only suitable if the walls are made of wood.

System Gain

How to strengthen the frame with spans of more than 6 meters? It is necessary to reduce the free span of the rafters. For this, struts and racks are used. It is necessary to make reinforcement taking into account the layout, it is important that these elements do not interfere with the stay of people and harmoniously fit into the interior.

The struts are usually placed at an angle of 45 or 60 degrees to the horizontal plane. Racks cannot be supported on the floor span. They are allowed to be installed on the underlying walls or beams and trusses thrown between the walls.

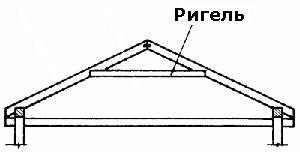

Tightening is necessary to reduce thrust. Because of him, the rafters can simply disperse. This is especially true for systems with hanging beams. To assemble the frame, use two puffs, which are attached on both sides of the rafters. Fixation is carried out on self-tapping screws, nails or studs.

At the top, the rafters rest on an intermediate or ridge run. Depending on the chosen system, location and width of the span, it is made of timber with a cross section of 50x100 to 100x200 mm. Fastening is carried out on connecting metal plates, bolts or nails.

crate

Before starting work at this stage, it is required to lay a waterproofing material. Builders recommend using a vapor-diffusion moisture and wind-protective membrane. It is more expensive than plastic film, but provides better protection. Your home is not a reason to save money.

The roof requires fixing the crate. The type depends on the chosen roofing material. For metal, a sparse crate made of boards 32-40 mm thick will suffice. Under bituminous tiles, a solid crate of 25-32 mm boards or moisture-resistant plywood is needed.

Ventilation of the under-roof space

Before proceeding to the stage of laying the roof, it is worth considering the ventilation of the under-roof space. This will protect the structure from mold, fungus and destruction.

Proper arrangement of ventilation under the roof will protect the structure from the appearance of fungus

Proper arrangement of ventilation under the roof will protect the structure from the appearance of fungus For ventilation it is necessary to provide:

- air flow through the eaves (the filing of the cornice is made with a rarefied board or special perforated spotlights);

- air movement under the coating (there should be a gap of 2-3 cm between the insulation and the roof);

- air outlet in the area of \u200b\u200bthe ridge (for this, a ridge and / or point aerator is installed on the roof).

Roofing

The type of roofing is selected from aesthetic and economic considerations. It is also worth studying the offers of manufacturers and finding out the permissible slope. For example, bitumen shingles are not recommended for laying at a slope of more than 45 °.

Seam roofing is a lightweight, fireproof and durable coating.

Seam roofing is a lightweight, fireproof and durable coating. The wall material must provide reliable waterproofing. Its installation is carried out in strict accordance with the manufacturer's instructions. There are five most common types of coverage: roof insulation.

I greet you dear colleagues of my Internet project! described in detail in this article. The roof or covering of a building is made to protect against precipitation, rain and melt water, in addition to thermal insulation. The roof of the premises is designed to be waterproof, moisture resistant, resistant to aggressive environments, solar radiation, and frost. A roof over your head must be economical, durable and light. we are talking about the roof of the house with your own hands - a step-by-step video, which, among other things, tells how to hold the loads of your weight, wind, snow.

INTERESTING VIDEO

How to make a roof at home with your own hands

Do-it-yourself construction of a roof truss system begins with the installation of a reinforced concrete belt along the top of the stone walls of the house. For houses built from logs or timber, it is not necessary to do it. The reinforced belt is designed to strengthen the top of the masonry and level the horizontal mark of all the walls of the house.  types of truss systems When pouring concrete, galvanized studs are inserted into the reinforcing cage of the belt, which will serve as fastening of the Mauerlat to the base of the armored belt. The studs should be of such length that they protrude from the Mauerlat by 2-3 cm. The Mauerlat is made from a bar with a section of 150x150 mm or 20x20mm, and serves as the basis for the truss system itself. The size of the cross-section of the Mauerlat depends on the power of the truss system, the weight of the roofing. Naturally, the more load the Mauerlat experiences, the stronger it should be.

types of truss systems When pouring concrete, galvanized studs are inserted into the reinforcing cage of the belt, which will serve as fastening of the Mauerlat to the base of the armored belt. The studs should be of such length that they protrude from the Mauerlat by 2-3 cm. The Mauerlat is made from a bar with a section of 150x150 mm or 20x20mm, and serves as the basis for the truss system itself. The size of the cross-section of the Mauerlat depends on the power of the truss system, the weight of the roofing. Naturally, the more load the Mauerlat experiences, the stronger it should be.  fastening the Mauerlat When building a roof with your own hands, one should not forget about laying waterproofing on the armored belt before laying the Mauerlat on it. In this capacity, roofing material in two layers is quite suitable. Mauerlat must be tightened on the studs with galvanized nuts to eliminate the risk of corrosion. It is necessary to use the building level so as not to disturb the horizontal laying of the Mauerlat. Before making a roof with your own hands, all wooden elements of the truss system must be treated with an antiseptic to prevent wood rotting. Next, the rafter legs are installed. As rafters, a board with a section of 150x50 mm or timber is used. In addition, you will need various bars, boards of different sections for the installation of spacers, crossbars, struts, screeds and other connecting elements. Depending on the type of roof chosen, rafters are installed, layered or hanging. For hip roofs, diagonal rafters and rafters are used - these are short rafter legs that support the diagonal rafters on both sides and rely on the Mauerlat. When the roof of a house is erected with your own hands, an assistant is needed, because it is impossible to do such work alone.

fastening the Mauerlat When building a roof with your own hands, one should not forget about laying waterproofing on the armored belt before laying the Mauerlat on it. In this capacity, roofing material in two layers is quite suitable. Mauerlat must be tightened on the studs with galvanized nuts to eliminate the risk of corrosion. It is necessary to use the building level so as not to disturb the horizontal laying of the Mauerlat. Before making a roof with your own hands, all wooden elements of the truss system must be treated with an antiseptic to prevent wood rotting. Next, the rafter legs are installed. As rafters, a board with a section of 150x50 mm or timber is used. In addition, you will need various bars, boards of different sections for the installation of spacers, crossbars, struts, screeds and other connecting elements. Depending on the type of roof chosen, rafters are installed, layered or hanging. For hip roofs, diagonal rafters and rafters are used - these are short rafter legs that support the diagonal rafters on both sides and rely on the Mauerlat. When the roof of a house is erected with your own hands, an assistant is needed, because it is impossible to do such work alone.  features of the hip roof rafters With any rafter system, the lower end of the rafter rests on the Mauerlat, and sometimes on the ridge with the upper end, and in some cases on the opposite rafter. Thus, roof trusses are formed, which are connected by a ridge beam or two boards at an angle from opposite sides and forming a ridge. The rafter legs are strengthened by installing spacers and struts, braces and stretch marks, crossbars, which generally give the rafter structure the necessary rigidity and strength. The step of the rafter legs when assembling the roof with your own hands is calculated based on the loads expected on them. During the construction of a gable roof, the truss system looks like triangles placed in a row, connected at the top with a longitudinal bar. With hip roofs, the ridge at the ends, as it were, bifurcates and forms two diagonal (diagonal) rafters on each side. As a result, four main rafter legs are obtained, which carry the entire load from the lathing, roofing, layers of vapor and waterproofing and insulation. Therefore, the construction of such a structure as a hip roof must be taken seriously when you need to make the roof of the house yourself.

features of the hip roof rafters With any rafter system, the lower end of the rafter rests on the Mauerlat, and sometimes on the ridge with the upper end, and in some cases on the opposite rafter. Thus, roof trusses are formed, which are connected by a ridge beam or two boards at an angle from opposite sides and forming a ridge. The rafter legs are strengthened by installing spacers and struts, braces and stretch marks, crossbars, which generally give the rafter structure the necessary rigidity and strength. The step of the rafter legs when assembling the roof with your own hands is calculated based on the loads expected on them. During the construction of a gable roof, the truss system looks like triangles placed in a row, connected at the top with a longitudinal bar. With hip roofs, the ridge at the ends, as it were, bifurcates and forms two diagonal (diagonal) rafters on each side. As a result, four main rafter legs are obtained, which carry the entire load from the lathing, roofing, layers of vapor and waterproofing and insulation. Therefore, the construction of such a structure as a hip roof must be taken seriously when you need to make the roof of the house yourself.  fastening of truss elements When constructing a gable roof, the first two structures of the truss system, in the form of triangles, are assembled on the ground and then raised to the roof. They are temporarily strengthened with spacers and immediately connected with a ridge beam or boards on both sides. After that, the rest of the rafter legs are mounted. For the convenience of workers, even before the construction of the truss system, floor beams are laid on the Mauerlat, on which temporary flooring is laid. The rafter system is fastened, in addition to tie-ins and cuts, with iron brackets, metal corners, self-tapping screws and nails. To create a rigid frame of the truss system, various struts, crossbars, ties, stops are used. If it is required to lengthen the rafter legs, this is done by splicing two rafter boards with installation at the junction of the short ones on both sides with a length of at least 50 cm. ^

fastening of truss elements When constructing a gable roof, the first two structures of the truss system, in the form of triangles, are assembled on the ground and then raised to the roof. They are temporarily strengthened with spacers and immediately connected with a ridge beam or boards on both sides. After that, the rest of the rafter legs are mounted. For the convenience of workers, even before the construction of the truss system, floor beams are laid on the Mauerlat, on which temporary flooring is laid. The rafter system is fastened, in addition to tie-ins and cuts, with iron brackets, metal corners, self-tapping screws and nails. To create a rigid frame of the truss system, various struts, crossbars, ties, stops are used. If it is required to lengthen the rafter legs, this is done by splicing two rafter boards with installation at the junction of the short ones on both sides with a length of at least 50 cm. ^

Laying the crate

INTERESTING VIDEO

How to make a roof at home with your own hands

After almost all the work on the construction of the house is completed, the next step is always the installation of the roof. It is necessary to start arranging the roof after the walls are fully erected on a solid and reliable foundation. The roof can be considered the most expensive stage in construction, so many, trying to save money, undertake its installation on their own. However, in order to know how to make the roof of a house with your own hands, you need to understand the types of roofing and its design. The roof is an important part of any building, as it performs several functions at the same time: protecting the house from rain and moisture, aesthetic function and thermal insulation. That is why it is important to responsibly approach the independent arrangement of the roof and think over its device in advance.

After almost all the work on the construction of the house is completed, the next step is always the installation of the roof. It is necessary to start arranging the roof after the walls are fully erected on a solid and reliable foundation. The roof can be considered the most expensive stage in construction, so many, trying to save money, undertake its installation on their own. However, in order to know how to make the roof of a house with your own hands, you need to understand the types of roofing and its design. The roof is an important part of any building, as it performs several functions at the same time: protecting the house from rain and moisture, aesthetic function and thermal insulation. That is why it is important to responsibly approach the independent arrangement of the roof and think over its device in advance.

Roof types

Before proceeding with the preparation of materials, tools and drawings for the construction of the roof, it is necessary to determine the type of roof being erected. The roof of the house with your own hands can be of the following form:

Before choosing a particular type of roof, you need to observe which roof is most common. Very often, broken mansard roofs are erected even on small houses, because it allows you to use the attic space as a living room. At the same time, it is distinguished by simple installation and looks quite aesthetically pleasing. An important point: the level of complexity of the roof structure and the presence of additional elements on it directly depends on how large the house is in area and what kind of layout it has. Moreover, the more complex the roof structure, the more difficult it is to equip the truss system.

Preparatory stage

In addition to choosing the type of roof, it is necessary to think in advance what material will be used to cover the roof, since the design of the truss system will depend on this. This is due to the fact that any coating will exert loads, in the form of pressure on the rafters. Therefore, an important point is to think over what elements will be used for fastening and how to further strengthen the truss system. It is best to start building a roof with your own hands only if there is a correctly executed drawing that can become the basis for the work. For greater convenience of work, the drawing may contain separately rendered joints in the rafters, which contribute to the strengthening of all elements of the system. Ceramic tiles have the largest weight, so if this material is used to cover the roof, you should take care in advance that the walls, as well as the foundation, are ready for heavy loads. Below is a do-it-yourself roof drawings and photos that may be needed in the work.

An important point: in order to make a truss system, you need a coniferous tree with a moisture content of twenty percent, and on which there are no blue and knots. In addition, the following will also be required:

Construction of the truss system

The installation of rafters during the construction of the roof should begin with the arrangement of a reinforced concrete belt on top of the walls. If a timber was used to build a house, then this procedure should not be done. The reinforced concrete belt is necessary in order to strengthen the masonry of the walls and make the horizontal mark of the walls more even and without defects. In the process of pouring concrete, special studs should be inserted into the belt frame, necessary to secure the Mauerlat. Reinforced studs should be of such a length that they can be seen from the Mauerlat by about three centimeters. The Mauerlat itself should be made from a bar that has a section of 20 by 20 millimeters or 150 by 150 millimeters. Mauerlat is the basis for the construction of the truss system. When building a roof yourself, it is important to remember about waterproofing, which must be laid on a reinforced belt. To do this, you can lay roofing material in several layers. After that, a Mauerlat is already laid on top, which is fastened to the studs with nuts (galvanized nuts must be taken, as this will help avoid metal corrosion). When laying the Mauerlat, in order to perform strictly horizontally, you should use a level. An important point: before starting the construction of the truss system, all wooden parts must be treated with an antiseptic, as this will help make the structure as durable as possible.  Next, you need to install the rafter legs. For this, a beam with a cross section of 150 by 150 millimeters is suitable. You will also need boards of different sizes for arranging screeds, spacers or struts. Rafters can be made of layered or hanging type, depending on the type of roof.

Next, you need to install the rafter legs. For this, a beam with a cross section of 150 by 150 millimeters is suitable. You will also need boards of different sizes for arranging screeds, spacers or struts. Rafters can be made of layered or hanging type, depending on the type of roof.

INTERESTING VIDEO

We build the roof of the house with our own hands step by step - the device of the crate

After all the external rafters have been installed, they should be nailed to the crate. To create the crate, you will need boards with a thickness of two centimeters. Depending on the choice of roof covering, the lathing can be made with gaps or solid. Before proceeding with the arrangement of the crate, it is necessary to make waterproofing along the rafters. In the event that in the future it is planned to make a room out of the attic, it is best to pre-insulate the roof. To insulate the roof with your own hands, you should lay the heat-insulating material between the rafters. For this, mineral wool or polystyrene is suitable. If you do not carry out insulation immediately, even at the stage of construction of the roof, then later you will have to do it from the inside of the roof, which is rather inconvenient.

To make a cozy and warm room on the attic floor, you should lay a heater in 2 layers. In this case, it is necessary to ensure that each layer is not less than fifty millimeters thick. In addition to thermal insulation properties, insulation also acts as a soundproofing material. After laying the insulation, you need to lay a layer of vapor barrier. This is necessary so that condensation does not accumulate on the heat-insulating material. With self-construction of the roof, in order for it to become durable and reliable, it is necessary to follow all the recommendations and observe the phased implementation of all work on creating a roofing pie. And the final step in the construction of the roof is the overlap with roofing material. The most popular such material is slate, which has a low cost and is durable and reliable. In addition, there are such expensive materials for the roof as ondulin or euroslate. It all depends on financial capabilities and personal tastes.

Source: remontidei.ru

Do-it-yourself roof roofing

Starting to build a roof roof with your own hands, you must first decide: what type of roof will be used, whether an attic is needed, whether there will be an attic. There are several basic types of roof structures, each of which is complicated if necessary or at will.  Structurally, the roof is divided into flat and mansard roofs. Flat roofs are usually non-attic, with a slight slope of the structure. Mansard-type roof options are the most common roof structures, the installation of which uses special internal supports - rafters.

Structurally, the roof is divided into flat and mansard roofs. Flat roofs are usually non-attic, with a slight slope of the structure. Mansard-type roof options are the most common roof structures, the installation of which uses special internal supports - rafters.

INTERESTING VIDEO

Such roofs consist of elements called slopes. Mansard roofs are pitched and flat. Most often, a gable roof is used to install the roof of a house with one's own hands (this type is also called a gable roof). For individual buildings with a polygonal complex shape of the plan, multi-gable roofs are used. Installation of a multi-gable roof of the roof of a house requires good professional training and high qualifications during the work. There are other, less common types of pitched roofs:

- lean-to;

- tent;

- hip;

- half hip.

It would be wiser to correctly assess your capabilities before starting the roof installation. The complex structure of the roof will require a complex truss system for it and special practical skills.

roof roofing materials

How to make a roof at home with your own hands

How to make a roof at home with your own hands? This article was written to answer this question. Everyone has known everything about insulation materials and roofing for a long time, for this reason, in this article we will focus on how to properly make a frame for a roof.

Mauerlat for gable roof

Mauerlat is the basis that takes on the bulk of the structural loads. In plain language, the Mauerlat is the foundation on top of which the roof will be built. For the arrangement of the base, beams are used, with a cross section equal to 150 by 150 mm. They are installed in a parallel plane with the roof ridge.  The fastening of the Mauerlat beams must be extremely reliable, this is done so that the roof is not afraid of wind and weather disasters. Ideally, these actions are carried out even when the walls are being built. To do this, you need to lay the top four rows of bricks with thick wire. This wire is called wire rod, and its location should be with a meter gap. The middle of the wire should be in a brick wall, and its ends, which hang freely, should be of such a length that it is enough for the subsequent strapping of the timber. In the event that the house project does not provide for plastering, then the installation of the outer edge of the wire must be carried out inside the solution, so it will not be noticeable. The important point is that the Mauerlat must recede from the edge of the wall by at least 100 mm. To protect the beams from decay, only a few layers are placed under them.

The fastening of the Mauerlat beams must be extremely reliable, this is done so that the roof is not afraid of wind and weather disasters. Ideally, these actions are carried out even when the walls are being built. To do this, you need to lay the top four rows of bricks with thick wire. This wire is called wire rod, and its location should be with a meter gap. The middle of the wire should be in a brick wall, and its ends, which hang freely, should be of such a length that it is enough for the subsequent strapping of the timber. In the event that the house project does not provide for plastering, then the installation of the outer edge of the wire must be carried out inside the solution, so it will not be noticeable. The important point is that the Mauerlat must recede from the edge of the wall by at least 100 mm. To protect the beams from decay, only a few layers are placed under them.

INTERESTING VIDEO

Strengthening the roof frame

When building a roof, a prerequisite is the arrangement of a reliable frame.

A frame is a truss system attached to a Mauerlat. Be sure to take into account that if the length of the beams is more than 4.5 m, then you will additionally have to mount runs.  The optimal section of the beams used to build the roof frame in a brick house is 70 by 150 mm. The fastening of the rafters on the Mauerlat is carried out using a special cutout, which is fixed with twenty-centimeter nails. Nailing should be done according to this principle:

The optimal section of the beams used to build the roof frame in a brick house is 70 by 150 mm. The fastening of the rafters on the Mauerlat is carried out using a special cutout, which is fixed with twenty-centimeter nails. Nailing should be done according to this principle:

- The first nail is nailed through the rafter to the Mauerlat in a diagonal plane;

- The second nail is driven in exactly the same way, only from the reverse side;

- The third nail is driven at an angle of 90° from above.

This method of fastening the truss system does not allow it to move from side to side.

This method of fastening the truss system does not allow it to move from side to side.

The upper ends of the rafters are fastened with an overlap, it is on the other. One beam, with its end should overlap the parallel beam. In the upper part, they are also fastened with nails, although bolts can also be used for this.

On this, the work on arranging the frame can be considered completed, it remains only to lay the roofing cake.

How to make a roof at home with your own hands video tutorial

INTERESTING VIDEO

How to build a roof at home: video + instructions

The fundamental structures of the house will be exposed to the destructive effects of external factors without a solid, reliable roof. In order to save money, homeowners often do all the roofing work themselves. It should be borne in mind that this stage of construction is as important as laying the foundation or erecting walls. Moreover, before starting work, it is necessary to determine what type of flooring is suitable for a house under construction? Table of contents:

Difficulties in choosing a roof structure: information for reflection

Usually, at the initial stage of design, several types of "roofing" attract attention, differing in the complexity of the work, the amount and type of material. The erected roof of the house with your own hands should not retain precipitation on the surface, withstand gusts of wind, and please with its appearance.  If we briefly characterize the variety of designs available for independent execution, we get the following accents:

If we briefly characterize the variety of designs available for independent execution, we get the following accents:

- The method of erecting a frame with one gentle slope is the most economical and simple to perform.

- A roof with two slopes, traditionally most in demand among the owners of houses, cottages, it is enough to correctly position and strengthen two simple slopes between them. The work is done quickly and easily.

- The four-slope design will look elegant, it can vary from tent to hip, half-hip. It is more complex, but it also gives maximum opportunities for creating a unique exterior of the building.

- The hip version is a frame that is gentle on 4 sides, two opposite surfaces of which make up regular triangles, and the other two are trapezoids.

- The half-hip variety is a kind of constructive symbiosis, combining the features of a gable and hip design, characterized by broken roof lines and complex execution. Strict proportions of four triangular slopes under one peak and harmonious execution distinguish the roofing "tent" in the form of a pyramid.

- The broken attic structure looks original with characteristic kinks in the middle of the slopes or bevels on the vertical sides. As a rule, compatriots want to get additional square meters of living space when building a roof, using an attic for this purpose.

Attention! Before you make the roof of the house, it should be noted that the increase in the load on the ceiling and the increase in the area of \u200b\u200bthe house is directly proportional to the increase in additional fasteners. A large number of slopes leads to an increase in labor costs for its construction. A novice builder should not take on the construction of complex structures, because. this requires serious calculations and a complex rafter scheme.

Attention! Before you make the roof of the house, it should be noted that the increase in the load on the ceiling and the increase in the area of \u200b\u200bthe house is directly proportional to the increase in additional fasteners. A large number of slopes leads to an increase in labor costs for its construction. A novice builder should not take on the construction of complex structures, because. this requires serious calculations and a complex rafter scheme.

INTERESTING VIDEO

The dependence of the operational characteristics of the roof on the type of roof

The type of future decorative coating affects the truss system, the choice of the section of wooden elements. For example, when tiling ceramics, the strongest frame should be made, because. piece material has a much greater weight than even slate or metal sheet. The complexity of the roof structure, its area, the angle of inclination and the type of coating affect the consumption of materials. In turn, the slope is performed based on the area of the roof and the type of roofing material: metal, ceramic, bituminous tiles; slate; soft roll materials, metal sheets, etc.

Multi-layered roofing "robe"

Having decided on the choice of the shape of the roof, a drawing is made, where the main elements are indicated: the truss system, supports, nodal connections, thermal insulation, waterproofing, roofing. In the simplest case (a flat version of the roof), the layering of the cake is as follows:

- ceiling covering;

- vapor barrier layer;

- insulation;

- strengthening screed;

- waterproofing layer.

With a pitched roof, the main element is the rafter frame, which holds the entire load and consists of:

With a pitched roof, the main element is the rafter frame, which holds the entire load and consists of:

- Mauerlat;

- rafters;

- crates;

- crossbars;

- puffs.

- waterproofing;

- insulation;

- vapor barrier coating;

- counterlattice;

- roof.

To hold the weight, coniferous tree material of a certain moisture content (20%) is used, without flaws in the form of knots. For work, you will still need fasteners (staples, screws, nails, self-tapping screws), the necessary tools, equipment.

The order should not be violated: the technology of erecting a pitched roof

Stage # 1 Formation of a reinforced base for the rafters A layer of reinforced concrete is formed along the upper crown of the masonry of the walls of the house, increasing the bearing capacity of the structures and leveling them in a horizontal position. It is not necessary to reinforce the walls if they are made of logs or timber. Studs are attached to the liquid solution of the belt, which are fasteners to the base of the reinforcing screed for the Mauerlat, a bar with a section of 150x150. In this case, the ends of the studs should protrude 30 mm from the support beam - the skeleton for the truss frame. The cross section of the supporting structure is the greater, the more powerful the rafter design and the weight of the roof.

INTERESTING VIDEO

The reinforced edging before laying the Mauerlat must be waterproofed, for example, with roofing felt. At the same time, in order to reduce the risk of decay, the minimum distance of the support beam from the wall must be maintained at least 10 cm. The support log is fixed on the protruding studs with nuts with a non-corrosive coating. Mauerlat beams are laid strictly parallel to the ridge. Attention! All stages of work on the construction of the roof are carried out with constant monitoring of compliance with the horizontal. For this, the building level is used. Stage # 2 Selection of wooden elements The stage of installation of compass-like structures is preceded by a preliminary wooden blank (150x50), you can use timber, small fragments of boards of different sizes and sections, which will be used as crossbars, spacers, ties, struts, strengthening the rafter legs and increasing strength the whole structure.  The frame, which bears the main load, is a rafter fastened to the Mauerlat. If the hip option is chosen, then shortened “legs” are also needed that support the diagonal rafter laying on both sides (spiders) standing on the Mauerlat. They should be 5x15 cm in section and fasten the rafter supports. Stage # 3 Mounting the truss frame

The frame, which bears the main load, is a rafter fastened to the Mauerlat. If the hip option is chosen, then shortened “legs” are also needed that support the diagonal rafter laying on both sides (spiders) standing on the Mauerlat. They should be 5x15 cm in section and fasten the rafter supports. Stage # 3 Mounting the truss frame

- In any case, when decorating the frame with rafters, one of their ends is placed in a special recess in emphasis on the Mauerlat, and the other rests on the ridge or lies on the opposite supporting element. In the lower part, the rafters are additionally nailed to the Mauerlat with nails with a working rod length of 20 cm. Wooden supports are also fixed between themselves with bolts. To do this, nests of the desired diameter are drilled in the tree.

Important! Before building a roof with two slopes, pine or larch wood is pre-treated with refractory antiseptic compounds. The first two triangular frames are assembled near the house, on the ground, in finished form they rise to the Mauerlat, where they are immediately temporarily fastened with spacers and joined with the ridge structure. Only after that the rest of the rafters are installed.

- Between themselves, the "legs" are located at a certain distance, based on the load. The simplest gable roof scheme is nothing more than triangles lined up in a row, the tops of which are mounted on a longitudinal beam.

- The step between the elements of the frame should be such as to support the weight of the crate, finish coating, the load from vapor and waterproofing, and insulation.

- The angle of inclination is an important detail in construction. For each region, it is selected specifically. In cold conditions with an abundance of precipitation, the best option is 40-45 °. In regions with windy weather, a slope of 20° should be adhered to. Hot dry areas allow the use of an angle with the lowest value of 3°.

INTERESTING VIDEO

Stage # 4 Sheathing Stuffing of the sheathing is done after all the rafters have been installed. It maintains the necessary gap between the heat insulator and the waterproof coating that removes the resulting condensate. A waterproofing material is laid on it, which prevents the penetration of moisture into the room and passes vaporous emissions from a warm room into the insulation. The crate is mounted on the rafters to hold the roof. For this, large-sized integral boards (about 2 m) with a thickness of 25 cm are useful. Based on the type of coating, they stuff a solid (for tiles, roll coating) or trellised crate (slate, metal sheet), fastened perpendicular to the rafters. The joints between the boards, not exceeding a gap of 5 mm in size, must be fixed on supports. Stage # 5 Heat, steam, waterproofing

- You can insulate the roof with mineral wool, carefully laying it in the space between the rafters. Insulating materials "extinguish" noise.

- A vapor barrier membrane (reinforced film) is stretched over the top of the mineral wool to prevent the insulation from getting wet. It should cover the frame with some margin, designed to change the parameters in the event of thermal expansion. Be sure to ensure tight contact of the film with external walls, pipes. If it is necessary to glue the canvases together, this must be done carefully, obtaining a holistic connection.

- Ventilation ducts also contribute to maintaining a special microclimate. To do this, small gaps should be left in the crate: 2 or even 3 channels on each side.

Stage # 6 Installation of the roofing The finishing stage is to correctly lay the roofing elements directly on the crate so that they withstand the loads and create an airtight coating. The laying direction is "right to left" and "bottom up". The easiest way (and cheaper), which does not affect reliability at all, is to use slate. He is unpretentious in installation. This is the option that is suitable when arranging the roof for the first time with your own hands. Don't forget the drainage system. It must be activated along the entire perimeter of the roof, and effectively remove precipitation in the required direction and in the required amount. The arrangement of the roof does not take a critically long time, provided that the preparatory stage is carefully completed, the technology for performing the work is observed. No need to rush to buy cheap materials. And you should also carefully study the theoretical material, watch a video on how to properly build a roof. At a sufficient level, master the “basics” of working with metalwork and woodworking tools.

Source: ofacade.ru

INTERESTING VIDEO

Self-construction of the roof of a private house

The sequence of stages of the construction of the roof is as follows:

In order for the roof to be securely fixed, care must be taken to securely connect it to the wall of the building. If a wooden house is being built, then the Mauerlat is not required - this element is the upper crown of timber or logs. In this case, fastening to the wall is carried out using special "floating" fasteners. They are sold ready-made, most often they are called sleds. This version of the roof device allows the entire structure to slightly shift when the walls shrink without damage and deformation.  "Sliding" fastening in a wooden house A similar situation arises with a frame house. In this case, the upper wall trim will be the Mauerlat. It is attached to the racks of the frame with a gash using corners, staples or nails.

"Sliding" fastening in a wooden house A similar situation arises with a frame house. In this case, the upper wall trim will be the Mauerlat. It is attached to the racks of the frame with a gash using corners, staples or nails.  Methods for attaching rafters to the strapping in a frame house The construction of a roof made of brick, concrete blocks or concrete involves fastening through a Mauerlat. In this case, there are several ways. There are four ways to put the Mauerlat on the wall:

Methods for attaching rafters to the strapping in a frame house The construction of a roof made of brick, concrete blocks or concrete involves fastening through a Mauerlat. In this case, there are several ways. There are four ways to put the Mauerlat on the wall:

- on staples;

- on studs;

- for anchor bolts.

Mauerlat can be fixed on brackets. In this case, wooden blocks are laid in the masonry from the inside. They should be located at a distance of 4 rows from the edge. One side of the bracket is attached to the Mauerlat, and the other to the same bar in the masonry. The method can also be classified as simple. It is not recommended for large buildings with high loads.  Mauerlat fastening on brackets. In the masonry of the wall, antiseptic wooden bars are provided in increments of 1-1.5 m. Do-it-yourself fastening when installing the roof can be done through studs or anchor bolts with a diameter of 10-12 mm. Fasteners are laid in the masonry. A Mauerlat is temporarily placed on the edge, you need to lightly hit it with a hammer. After that, recesses remain on the beam in the places of fasteners. On them you need to make holes for the studs. After that, the timber is put on the fasteners and the nuts are tightened. The method is ideal for walls made of lightweight concrete in the presence of a monolithic armo-belt.

Mauerlat fastening on brackets. In the masonry of the wall, antiseptic wooden bars are provided in increments of 1-1.5 m. Do-it-yourself fastening when installing the roof can be done through studs or anchor bolts with a diameter of 10-12 mm. Fasteners are laid in the masonry. A Mauerlat is temporarily placed on the edge, you need to lightly hit it with a hammer. After that, recesses remain on the beam in the places of fasteners. On them you need to make holes for the studs. After that, the timber is put on the fasteners and the nuts are tightened. The method is ideal for walls made of lightweight concrete in the presence of a monolithic armo-belt.

Fastening rafters to Mauerlat

In houses made of brick or stone, it is more reasonable to carry out with the help of a rigid attachment of the rafters to the Mauerlat. In this case, you can use both layered and hanging systems. The design assumes two ways:

- with a notch;

- without notch.

Connection with and without cutting In the first case, the rafters are hemmed with a slope so that they are tightly adjacent to the Mauerlat. For the removal of the cornice, fillies are provided. They are attached to the leg with an overlap of at least 1 m. Rigid fixation of the knot should be done using self-tapping screws, nails or staples. But the assembled frame will have greater reliability if metal corners with holes for self-tapping screws are used for fixing.

Connection with and without cutting In the first case, the rafters are hemmed with a slope so that they are tightly adjacent to the Mauerlat. For the removal of the cornice, fillies are provided. They are attached to the leg with an overlap of at least 1 m. Rigid fixation of the knot should be done using self-tapping screws, nails or staples. But the assembled frame will have greater reliability if metal corners with holes for self-tapping screws are used for fixing.  The method without cutting often does not involve the use of fillies. In this case, the frame overhang is provided by the beams themselves. This option is simpler than the previous one, since it does not require high accuracy. It is suitable for beginners. For a snug fit to the Mauerlat, in this case, use persistent bars or boards. Rigid fixation, as in the previous case, is performed with metal corners on both sides.

The method without cutting often does not involve the use of fillies. In this case, the frame overhang is provided by the beams themselves. This option is simpler than the previous one, since it does not require high accuracy. It is suitable for beginners. For a snug fit to the Mauerlat, in this case, use persistent bars or boards. Rigid fixation, as in the previous case, is performed with metal corners on both sides.

Fastening rafters to the wall

INTERESTING VIDEO

How to make a roof at home with your own hands

Any building consists of three main parts - the supporting structure, the box and the upper structure. It is the upper structure that determines the functionality of the building, its reliability and comfort of living. However, it may well be done by hand, if you study the features and principles of building the roof of the house.

Types of roofs

Depending on the shape of the structure of the box of the building and its size, various roof structures are used, many of which can be made by hand.

gable roofs

The most common house roof structures that are easy to calculate and do it yourself.  The angle of inclination of the rafter legs varies in the range of 20 - 50 °, it is selected depending on the magnitude of wind and snow loads acting in the construction region. Making such a roof with your own hands is not difficult. The simplicity of the design allows you to correctly calculate the need for materials, avoiding overspending.

The angle of inclination of the rafter legs varies in the range of 20 - 50 °, it is selected depending on the magnitude of wind and snow loads acting in the construction region. Making such a roof with your own hands is not difficult. The simplicity of the design allows you to correctly calculate the need for materials, avoiding overspending.

hip roofs

Such structures differ from gable structures - the presence of additional side planes with a certain slope.  Obviously, it is somewhat more difficult to correctly calculate such a roof of a house than a gable roof, but it is also quite affordable for do-it-yourself construction. Danish hip - the roof of the house is formed in such a way that only part of the pediment is cut off. This is done in the case when it is necessary to increase the volume of the attic room.

Obviously, it is somewhat more difficult to correctly calculate such a roof of a house than a gable roof, but it is also quite affordable for do-it-yourself construction. Danish hip - the roof of the house is formed in such a way that only part of the pediment is cut off. This is done in the case when it is necessary to increase the volume of the attic room.  The rounding of the roof in its lower part is an atypical case, usually all slopes are straight. Norwegian hip - the roof is made with an overlap in the upper part of the pediment, which makes it possible, in particular, to arrange a canopy over the balcony or loggia elements of the building.

The rounding of the roof in its lower part is an atypical case, usually all slopes are straight. Norwegian hip - the roof is made with an overlap in the upper part of the pediment, which makes it possible, in particular, to arrange a canopy over the balcony or loggia elements of the building.  Multi-pitched roofs - such a roof is arranged for purely design reasons, without sacrificing its functional qualities. At the same time, truss systems are designed using computer programs, and execution is hardly possible with your own hands without special skills. Such roofs can only be properly made by qualified specialists.

Multi-pitched roofs - such a roof is arranged for purely design reasons, without sacrificing its functional qualities. At the same time, truss systems are designed using computer programs, and execution is hardly possible with your own hands without special skills. Such roofs can only be properly made by qualified specialists.  For the final coating of such roofs, small-format materials in the form of tiles are used as the final outer coating. Large format materials can be used inefficiently.

For the final coating of such roofs, small-format materials in the form of tiles are used as the final outer coating. Large format materials can be used inefficiently.

Rafter systems

The upper structure of the building is a complex structure, which consists of a number of elements:

Installation of the hip roof truss system

Before proceeding with it, you need to properly organize the workplace:

- put the ceiling beams in place and fix them;

- lay a draft attic floor in accordance with the project.

As a preparatory measure, it is imperative to make a draft design of the truss system, which will allow you to correctly calculate the need for materials depending on the angle of inclination of the slopes, using graph paper, a pencil and a ruler, you can prepare drawings of the main elements of details on the roof of the house with your own hands.

Installation of the spinal beam (ridge beam)

With a symmetrical installation of slopes, the axis of the ridge beam will pass strictly along the longitudinal axis of the building:

With a symmetrical installation of slopes, the axis of the ridge beam will pass strictly along the longitudinal axis of the building:

- using the dimensions from the draft design, you need to cut out and install in place the bed - the supporting element of the ridge beam through the racks;

- cut out the racks, install them on the bed and fix them vertically with temporary jibs;

- install the ridge beam on the racks and fix it to the racks using plates and self-tapping screws with a length of at least 50mm. Make fasteners on both coinciding planes (4 places);

- carefully set the resulting structure along the longitudinal axis of the building, check the verticality, finally fix the racks on the bed with metal corners (8 places - 4 plates and 4 corners);

- cut in place and install the rafters connecting the ridge beam with the Mauerlat corners, fasten with plates and corners. If all the diagonal rafters are the same size, the symmetrical roof is correct;

- rafter legs must be installed in cuts to ensure emphasis on the ridge beam and Mauerlat. Therefore, it is advisable to pre-make an appropriate template from a lighter board (25 mm) and cut rafter legs along it;

- the installation step of the rafters is best coordinated with the width of the insulation from which the roofing cake will be formed. This will save materials and time in its manufacture;

- after installing the rafters, it is advisable to immediately install the stiffening elements of the system - struts and trusses, the parts are cut out in place;

- sprigs are also made locally, taking into account the dimensions of the insulation and are installed with fastening through the plates;

- the entire truss system along the perimeter of the building must be cut, taking into account the size of the overhang along the cord. If necessary, to increase the overhang, you can install fillies - rafter extensions.

INTERESTING VIDEO

Continuation of work depends on the prevailing weather conditions. If the weather is stable and the forecast is favorable, you can begin to form a roofing pie. Otherwise, this operation can be performed after installing the roof finish, from the inside.

Formation of the roofing cake

The purpose of this element is to save heat in the house. It is calculated that in houses with insulated attics, heating costs are reduced by 20-25%. Thus, the cost of insulation will return in the form of savings due to energy consumption.  The order of work is as follows:

The order of work is as follows:

crate

This element is the bearing surface for the final roofing, in addition, it holds together the entire structure of the upper structure of the house. The crate happens:

- solid - the distance between individual boards can be 5 - 10 mm;

- sparse - the distance between individual elements is up to 250 mm;

- rare - the distance between the boards is up to 900 mm;

- counter-lattice - is performed to provide a ventilation opening under the finish coating of corrugated board or tiles.

A continuous crate is used when using small-format materials such as tiles as a finishing coating. The material for the lathing is usually a cut or unedged board with a thickness of 25 mm. Do not use boards with a width of more than 15 cm, constantly exposed to moisture, the boards of the crate are warped. The result may be swelling of individual elements of the roof with a violation of its continuity. The crate on the roof of the house, due to the ease of execution, can be done with your own hands.

Roof top coat installation

Depending on the complexity, the roof of the house can be entrusted to specialists, and a simple gable roof can be properly covered with your own hands. In the process of framing and installing the finishing coat, it is necessary to observe the order in which additional elements are installed on the roof, to do individual work out of turn, sometimes it is simply impossible without violating the mating elements.

Additional premises

When attaching additional verandas or rooms to the house, it must be borne in mind that the foundation in the extension will live an independent life for at least another five years. The roof will behave accordingly. Therefore, on the extension, it is necessary to provide for the possibility of free movement of its elements without losing the basic qualities.

Conclusion

Completion of construction is a crucial stage, however, even before starting work, it must be remembered that all wood used in structures must undergo antiseptic and fire-fighting treatment. Otherwise, all costs may be in vain. When starting to do the work with your own hands, you need to understand that each step needs to be considered and analyzed. I wish you success! What else to read on the topic?  How to make a gable roof video

How to make a gable roof video  How to install rafters with your own hands

How to install rafters with your own hands  Do-it-yourself shed roof at home

Do-it-yourself shed roof at home

Article author:

Article author:

Sergey Novozhilov is an expert in roofing materials with 9 years of practical experience in the field of engineering solutions in construction.

Source: proroofer.ru

INTERESTING VIDEO

How to make the roof of a frame house with your own hands

Finally, in my frame house, I reached the roof. It was December 15 outside and I realized that I didn’t have time to make the roof alone, but soon it would snow (and, as it turned out, it would rain), so I decided to call a team of builders I knew for help. Looking ahead, I’ll say that, to my delight, the main frame of 42 rafters with film, batten and counter batten was installed in just 11 hours by me and 4 lads (for the contacts of these giants, contact the comments or email). You understand, with photos of the process it’s tight, because in 11 hours there was no time even to eat or sit down. The task was tough - to do everything in one day. But we didn't deal with that either. And now about everything in order. I did the calculations for my roof in the text about the calculation of the section of the rafters. Let me remind you, the initial data:

The house is 8.75 meters wide + sheathing with an inch another 5 centimeters = 8.8 meters.  Accordingly, spans of floor beams:

Accordingly, spans of floor beams:  Let me remind you that the snow load in our region is 240-320 kg per m2, i.e. very serious. According to the calculations, the rafter should have a section of at least 176 mm. So I took a 190 x 45 mm rafter with a light margin (generally, it was 200 x 50 mm, but dried up).

Let me remind you that the snow load in our region is 240-320 kg per m2, i.e. very serious. According to the calculations, the rafter should have a section of at least 176 mm. So I took a 190 x 45 mm rafter with a light margin (generally, it was 200 x 50 mm, but dried up).

I talked about cutouts in the rafters in the text on how to make cutouts in the rafters correctly. In theory, everything sounded quite complicated, but in practice, the guys sawed and made cuts in all 40-odd rafters in an hour and a half, and this despite the fact that many were crooked and had to be leveled along the entire length to one size.

Now I’ll tell you in detail how the work went so that you can use it later. 1. We determine the center of the building from both gables, pull the thread. We put a flat board 150 × 50 along these threads, which will serve as a support for the ridge board and pin it to the floor lintels, as well as to the floor joists with an arbitrary step. It will show up in the next photo. 2. We set the supports for the ridge along the edges and the center of the building (in our case, according to the calculation for a roof angle of 26 degrees, they were 2.1 meters). Along the edges of the building, we nailed them to the sheathing (I already had a sheathing with an inch on the pediment), in the center we grab the support from below and make a mowing for it to the ceiling so that it does not fall.  3. We select the most even boards (in our case, two boards with a total length of 12.2 meters were enough, just a house 11.25 meters long and about 45 cm on each side for the gable overhang).

3. We select the most even boards (in our case, two boards with a total length of 12.2 meters were enough, just a house 11.25 meters long and about 45 cm on each side for the gable overhang).

We expose the horse.  The quality of the photo is not very good, alas. 4. We sort all the rafters, divide them into 3 piles: ideal, normal and very bad.

The quality of the photo is not very good, alas. 4. We sort all the rafters, divide them into 3 piles: ideal, normal and very bad.

We take the ideal ones on the first 2 rafters, which will act as patterns. To do this, we take the first ideal board, make a cutout for the ridge and apply it to it, but 3-4 centimeters higher. Now, from below, another person marks the place and depth of the cutout in the rafter so that it then sits there when lowered by 3-4 centimeters. 5. Now we attach 2 patterns of the resulting ones to the skate and see if there are any gaps. Not? Great, we apply them on the other pediment (suddenly the house is crooked?). In our case, the house was almost perfect + -5 mm, so that all the rafters turned out the same.  We give the patterns down, and there in an hour they saw 40 more pieces of the same for us (one I would saw them all day). They choose normal boards for the rafters, in the end they had to take very bad ones, but they were cut along the entire length to one size (190 mm).

We give the patterns down, and there in an hour they saw 40 more pieces of the same for us (one I would saw them all day). They choose normal boards for the rafters, in the end they had to take very bad ones, but they were cut along the entire length to one size (190 mm).  Outcome

Outcome  Beauty, right? 6. After all the usual rafters were installed, we moved on to the remote rafters (consoles), which are also the basis for the end board.

Beauty, right? 6. After all the usual rafters were installed, we moved on to the remote rafters (consoles), which are also the basis for the end board.  First, we put them on a temporary board nailed to the wall and attach them to the ridge. And after that we pull the threads (so as not to burst the console) and fill between the remote rafters and the usual ones with sheathing - jumpers.

First, we put them on a temporary board nailed to the wall and attach them to the ridge. And after that we pull the threads (so as not to burst the console) and fill between the remote rafters and the usual ones with sheathing - jumpers.  Wow high! In the end they look like this:

Wow high! In the end they look like this:

7. Now it's time to add temporary supports under the ridge.

7. Now it's time to add temporary supports under the ridge.  According to the calculation, with my slope and snow load, I need support under the ridge with a section of at least 100 × 100 in increments of 1100 mm (calculated using Norwegian software for calculating loads). Many put supports under the ridge 150 × 40 (like my temporary ones in the photo), but this is wrong, since the deflection strength in this case is considered according to the smallest section and is equal to 40 mm, and 40 mm does not hold my load. True, there is an option to make jibs on both sides between each each support, then they will be strong enough. 8. The next step was to stretch the waterproofing and stuff the counter-lattice.

According to the calculation, with my slope and snow load, I need support under the ridge with a section of at least 100 × 100 in increments of 1100 mm (calculated using Norwegian software for calculating loads). Many put supports under the ridge 150 × 40 (like my temporary ones in the photo), but this is wrong, since the deflection strength in this case is considered according to the smallest section and is equal to 40 mm, and 40 mm does not hold my load. True, there is an option to make jibs on both sides between each each support, then they will be strong enough. 8. The next step was to stretch the waterproofing and stuff the counter-lattice.

Note that the first short of the counter batten is pulled over the end of the rafter without waterproofing.  Waterproofing is not brought to the eaves so that the roof is better ventilated.

Waterproofing is not brought to the eaves so that the roof is better ventilated.  9. And now the turn of the battens has come with a step of 350 mm under the metal tile. Her lads did with the speed of the wind. I just managed to make all the cantilever outriggers with my partner, and they made a crate on both slopes and urged us on.

9. And now the turn of the battens has come with a step of 350 mm under the metal tile. Her lads did with the speed of the wind. I just managed to make all the cantilever outriggers with my partner, and they made a crate on both slopes and urged us on.  Oh, and tired of all the participants in this event! And this is the result:

Oh, and tired of all the participants in this event! And this is the result:

As a result, by 22-00 we did everything we wanted and went home. It remains for me alone to finish the cornices, gable overhangs and lathing in some places and, of course, to cover the roof with metal. Thus, it is possible to make a frame roof with a span of 9 meters and a load-bearing wall in the middle. If you want this cool team to come to your construction site, write to me (you can use the red box on the right of the screen)!

As a result, by 22-00 we did everything we wanted and went home. It remains for me alone to finish the cornices, gable overhangs and lathing in some places and, of course, to cover the roof with metal. Thus, it is possible to make a frame roof with a span of 9 meters and a load-bearing wall in the middle. If you want this cool team to come to your construction site, write to me (you can use the red box on the right of the screen)!

The roof of the house is one of the main components of the house. It is the upper structure of the building, without which it is difficult to imagine a comfortable stay. The main functions of the roof are protection from snow, rain and other precipitation, as well as keeping warm in the cold season and protecting against overheating in the summer months. In our years, there is a wide variety of roofs for every taste and budget. However, the most common and popular at any time are gable roofs, which are versatile, inexpensive and easy to install. We will talk about how to properly make a gable roof with our own hands in today's article.

The design of a gable roof is the most common in private construction. As the name of this type of roof implies, it is made in the form of two slopes or, more simply, in the form of a triangle. Such roofs are easy and quick to mount, they are quite durable and their appearance finds many fans, as it combines the look of a Russian hut and a modern building. With the necessary knowledge, you can do it yourself using the available tools.

The device of the truss system of a gable roof

The rafter system of a modern gable roof consists of many elements, each of which evenly redistributes the weight of the structure and correctly transfers it to the walls of the house. The figure below shows the construction of a gable roof of a house with its main nodes and elements of the truss system.

Let's analyze each of the elements shown in the diagram separately:

- The rafter leg is the main part in the design of the gable roof truss system, which is an inclined element laid through the entire roof. To create it, the most durable bars are selected, since the rafter leg, in addition to the weight of the roofing material and the batten, can bear the weight of precipitation in the form of snow;

- Mauerlat - the so-called "foundation" of the roof, which is the main support for the entire structure, which distributes the load on the walls. It is a bar or a thick board on which the rafter legs rest and which is a “gasket” between the wall and the roof;

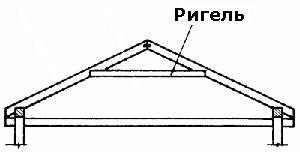

- Puff (screed) - a spacer that lies at the base of the triangle, reinforcing strength. The puff performs a dual function, since the ceiling is mounted to its lower part;

- Runs - ridge ones are attached in the upper part, side ones in the center of the rafter legs. The task of the runs is to keep the rafter legs from falling and "folding";

- Rack - located in the central zone, directly under the ridge. Serves as a support, transfers the load to the tightening;

- Lying - an additional element on which the rack rests;

- Sheathing - boards that are mounted across the rafters. The crate is designed to lay roofing material on it (in the simplest case) and to provide additional rigidity to the entire truss system.

This roof scheme is universal for many buildings, but depending on the complexity of the structure, special elements can be added here to give stability and rigidity to the entire truss system.

The slope of the gable roof

Choosing an acceptable roof angle is a significant task, but for many builders it fades into the background, which is not true. The so-called gable structures with straight slopes are considered standard. The optimal angle of inclination of a gable roof is on average 30 ° -45 ° (the angle at the base of an isosceles triangle is taken as the basis).

The choice of the angle of inclination will determine how well the upper part of the house will withstand the following factors:

The first two points must be taken into account with particular care, since a miscalculation in the choice of roof slope can cost large financial and health losses in the event of a collapse.

Example: the larger the angle, the lower the load on the roof from precipitation, but the threat of wind damage increases due to the windage created (the roof can simply be blown off). The noise effect will also increase if metal is chosen as the roofing material.

- Roll materials: the number of layers is pre-calculated. The more of them, the lower you can make the roof. Double flooring - from 10-15°;

- Type-setting elements: these include tiles (including soft ones) and slate. The angle of inclination of the rafters is set from 20 °;

- Metal tile: adhere to a slope of 14 °;

- Decking: its sheets should be placed at an angle of 12 °;

- Ondulin: it is allowed to adhere to an indicator of 6 °.

Thus, when designing a roof and choosing the angle of inclination, it is important to know in advance what kind of roofing material you will cover it with. As you can see, the minimum angle of inclination of a gable roof can be 6 °.

Types of truss systems for gable roofs

Most truss systems for gable roofs are divided into two main types - hanging and layered. The first type is the most common. Let's take a closer look at both types.

Hanging rafter gable roof system

This type of roof structures is used exclusively when the walls of the house are at a distance of up to 10 m from each other and there are no supporting floors between them. Rafters (legs) are joined only with the side parts of the house in the form of a Mauerlat. The downside of a gable roof with hanging rafters is the possibility of damage due to bursting load, since stretch marks are not provided between the rafters in this case.

Sloping roof truss system

The difference between layered structures is the presence of an additional support in the form of a wall or other support. The layered truss system is installed with supports that are attached to the intermediate walls. This design allows you to close large spans without compromising the rigidity of the entire truss system.

Separately, it is worth talking about several more types of gable roofs. By design, a gable roof can be made in the following versions:

- symmetrical gable roof;

- asymmetric gable roof;

- double pitched roof.

The differences between these designs are clear from the name. Depending on the project of your house and design solutions, the roof can be asymmetric, that is, have different angles of inclination at the base. Such a roof is a little more difficult to install than a conventional symmetrical roof, which has an isosceles triangle at its base, but it will not be difficult for an experienced craftsman to build such a structure.

A gable sloping roof is also very common. The rafters of such a roof seem to be slightly broken off at the base. Such roofs practically do not retain precipitation and allow you to win in the attic space for.

Often, novice builders, before designing and calculating the purchase of material, have questions about how to find out the length of the gable roof rafters. To do this, it is important at the design stage to know what the width of the building will be in order to select standard-sized rafters so that they do not have to be spliced, sacrificing their bearing capacity. Along with this, you must not forget about the angle of the roof. All of these factors will eventually affect the length calculation.

So, to calculate the length of the rafters of such a roof, you need to divide the triangle formed by the rafter system into two right-angled triangles. Further, knowing the width of the building and the angle of the roof, you can determine the height of the gable roof ridge. Knowing the two legs of a right triangle and using the Pythagorean theorem, we can calculate the hypotenuse of each right triangle, which is the required length of our roof rafters.

As a result, to determine the final length, another 30-50 cm must be added to the obtained value to ensure roof overhangs.

All calculations made to determine the height of the ridge (it is also the height of the pediment) and the length of the rafters are clearly shown in the image: