Connecting elements of wooden parts and structures. Secrets of making tight joints from wood. Wood Gluing Tool

Making furniture with your own hands is becoming increasingly popular due to the high cost of finished products, and due to the large number of source materials that have appeared in the public domain. At home, with a minimum set of appropriate tools, it is realistic to assemble viable furniture that will serve properly and please with its appearance. One of the most popular joining methods is gluing, which makes it possible to obtain strong, monolithic parts. Gluing can be used as an independent fastener or as a duplicating one, when using external elements, such as dowels, dowels or self-tapping screws.

Do-it-yourself glued wood

Before gluing, the parts are processed, this is done not only to clean the surface, but also allows you to open the wood pores. When applied, the adhesive composition penetrates through the pores into the wood structure, into the intercellular space, and when solidified, it forms a multitude of the thinnest threads (cobwebs) that reliably “seam” the workpieces together. The strength of a correctly made seam exceeds the strength of the wood itself; when testing for fracture, the part breaks not at the place of gluing, but along the whole tree.

Gluing a tree allows you to get products with better parameters than massive ones. In the process of gluing, elements that are suitable in texture and shades are selected, damaged, cracked and knotty areas are rejected. As a result, the strength of the glued parts is greater than that of the usual one, and by gluing the thinnest veneer onto the front surfaces, the products are given the appearance of the most valuable rocks. Wood glued according to all the rules warps, cracks and cracks much less than solid wood.

How to glue wood. Technology

There are several ways to connect parts when gluing.

- Gluing wood onto a smooth joint - joining smooth details without increasing the penetration area.

- Gluing on a microthorn - an increase in the penetration area by 2.5 - 5 mm due to the creation of a jagged relief on the part (using a milling cutter).

- Bonding on a toothed spike – increase in the penetration area by 10 mm due to the creation of a toothed spike.

- Gluing on a tongue-and-groove (thorn-groove, dovetail, oblique tenon) - additional grip due to the groove connection.

Although in certain situations where special conditions of use are expected, tongue and groove joints are relevant, in most cases the parts are glued to a smooth reveal. Modern adhesives penetrate deep into the structure and create a strong seam without additional sampling of wood.

How to glue boards together. Options

The wood to be glued must have a moisture index in the range of 8 - 12%, maximum - 18%. If there is a need to glue wet parts, a special compound is used; during the hardening process, it draws moisture from the wood. When gluing blanks with different moisture content, a difference of more than 2% is not allowed in order to avoid internal stress in the glue line due to deformation of the wetter part. The temperature of the glued workpieces varies between 15 - 20⁰С, so the work is carried out in warm rooms (18 - 22⁰С). In the cold, most compositions crystallize, which leads to a deterioration in the quality of gluing and makes the process difficult.

The final preparation of wood (planing, jointing, sanding) is carried out immediately before gluing in order to increase the permeability of the adhesive and avoid warping. It is important not only to select parts according to their dimensions, structure and external data, but also to arrange them correctly.

- When gluing along the length, only one type of sawing is used - tangential or radial;

- When gluing, both in length and in width, alternation of different parts of wood is not allowed - the core is laid with the core, sapwood (young, extreme part) with sapwood;

- Annual rings of adjacent blanks from boards or bars should be directed in different directions or at an angle to each other from 15⁰.

The standard thickness of furniture panels is 2 cm, but in order to glue wooden panels at home, when choosing boards for a shield, the estimated waste during processing is taken into account, so the workpiece is selected with a thickness of up to 2.5 cm. The excess will be removed during the primary processing, when defects are eliminated, and after gluing, when grinding the shield. If you dissolve a board 5 cm thick for a furniture board, you get two blanks with the same texture and shade, which increases the decorative effect of the product. For shields, boards of wood of the same species are selected, up to 120 mm wide, so that it is possible to process the edges of the shield with high quality, the length of the blanks should have a margin (2 - 5 cm).

Adhesives

Adhesives used for the manufacture of laminated wood fall into two main groups.

Synthetic - obtained on the basis of resins or polyvinyl acetate dispersions (PVA). They are characterized by increased strength of the resulting connection, moisture resistance, biostability. The disadvantages include the presence of harmful substances that can be released into the environment during operation and further operation. This is "famous" for compositions based on phenol-formaldehyde resins. Modern PVA dispersions and their derivatives are non-toxic and are commonly used in the domestic area and are considered universal for wood. The bulk of synthetic mixtures are ready for use. The epoxy adhesive needs finishing, to work with it the hardener included in the kit is mixed with epoxy resin.

Natural mixtures - animal, vegetable, mineral. They are safe, give a strong connection, but are produced in the form of semi-finished products that are prepared before use. How to glue a tree with them: when preparing, you must strictly follow the instructions and observe the dosages, otherwise the quality of the glue will not allow you to get a strong connection. To prepare the adhesive, it is usually necessary to dilute the powder concentrate with water to the desired consistency (may require a certain swelling period) or to melt the solid particles. Direct exposure to fire is not allowed, a “water bath” is used, in which the mass with the addition of water after swelling is melted to a homogeneous consistency.

How to glue a tree

When gluing wooden surfaces, the adhesive is applied to both parts in an even layer. The thickness of the layer depends on the type of glue, its consistency and the type of surfaces to be glued - the thinner the wood, the thinner the layer. The glue should moisten the part, but not excessively; when connecting the elements, an even roller should stand out. Adhesive streaks are removed from the surface as soon as they grab a little, with a scraper or spatula. Cured excess glue greatly spoils the appearance of parts and complicates their further processing.

How to glue a wooden blank.

How to glue a wooden blank.

After applying the adhesive, the parts withstand a certain period of time, this allows the composition to penetrate deeper, at the same time excess moisture evaporates, the concentration of adhesives increases. During exposure, it is not allowed to air the seam in a draft or dust it. Some types of natural glue (bone, skin) must be applied hot, instantly fastening the parts without aging, since the composition loses its properties as it cools.

Wood Gluing Tool

To obtain the most durable connection, when gluing, the wood is pressed in - compressed by means of special presses. At home, for these purposes, improvised tools and means are used - a vice, clamps, cam devices, metal corner frames with clamping mechanisms. The pressure during wood pressing is maintained in the range from 0.2 to 1.2 MPa. In production, large values are possible, at home such indicators are enough for the structural details to stick together.

Glued wood with your own hands.

Glued wood with your own hands.

Subject to the gluing technology, the adhesive seam is strong and reliable, and, unlike the method of connecting parts with metal fasteners, does not spoil the appearance.

For fans of creating household items on their own, a topic is open on FORUMHOUSE. How to organize a convenient corner for working with wood can be found in the article. The video about wooden elements in a country house shows interesting products made by users of the portal.

Due to the limited size of the tree, the creation of building structures of large spans or heights from it is impossible without connecting individual elements. Connections of wooden elements to increase the cross section of the structure are called rallying, and to increase their longitudinal length - splicing, at an angle and attaching to the supports - anchoring.

Increasing the workpieces in length is called splicing. The increase in blanks along the section is called rallying. Connections of wooden structures are classified according to various criteria. For example, by the type of work of the element and the work of the connection itself (connections on stretched bonds, connections on pliable bonds).

By the nature of the work, all the main connections are divided into:

- without special connections (frontal stops, cuts);

- with compressive bonds (shoe keys);

- with bonds working in bending (bolts, rods, nails, screws, plates);

- with ties working in tension (bolts, screws, clamps);

- with shear-shear bonds (adhesive joints).

According to the nature of the work of the joints of wooden structures, they are divided into pliable and rigid. Compliant are made without the use of adhesives. Deformations in them are formed as a result of leaks.

It is customary to distinguish between three groups of joints of wooden structures:

- Contact connections (without the use of working mechanical connections: notches and other "end-to-end" connections)

- Connections using mechanical connections (dowel: bolted, nailed; keyed, connections on washers, dowel plates, etc.)

- Adhesive and combined type joints

Connection Requirements

1. Reliability. In particular, it is recommended to minimize unfavorable (unreliable) types of work of wood in joints (work of wood for chipping, crushing across the fibers, stretching across the fibers). The so-called principle of fragmentation is closely related to the concept of reliability: "the smaller the connections and the more of them, the higher the reliability of the connection." In other words, ten small-diameter bolts are preferable to one bolt at the same metal costs, since in the first case, the wood works mainly for crushing (“reliable” type of wood work), and in the second case, for shear (“unreliable” type of wood work)

1. Reliability. In particular, it is recommended to minimize unfavorable (unreliable) types of work of wood in joints (work of wood for chipping, crushing across the fibers, stretching across the fibers). The so-called principle of fragmentation is closely related to the concept of reliability: "the smaller the connections and the more of them, the higher the reliability of the connection." In other words, ten small-diameter bolts are preferable to one bolt at the same metal costs, since in the first case, the wood works mainly for crushing (“reliable” type of wood work), and in the second case, for shear (“unreliable” type of wood work)

2. Strength. In particular, the desire for equal strength with the main part of the structure, the absence of weakening (holes) in the section.

3. Reduced labor intensity in the manufacture and installation of structures (manufacturability)

4. Deformability. For example, in contact joints, the value of the ultimate deformation of the collapse is limited

The work of wood in joints. Types of wood work for crushing across and at an angle to the fibers, as well as for chipping, are unfavorable. It is these types of wood work that accompany the work of joints, and it is they that are most often a direct or indirect cause of structural failure.

Collapse. The work of wood on crushing across and at an angle to the fibers is characterized by increased deformability and low strength. The “force-strain” diagram during the collapse of wood across the fibers reflects the effect of flattening of tubular wood cells. There are three types of crush:

- n collapse over the entire surface (R cm = 1.8 MPa, the most unfavorable type of collapse)

- n collapse into parts of length

- n collapse on part of the surface (under the washers) (R cm = 4 MPa)

The increase in strength in the latter case is explained by the reinforcing effect of the wood fibers surrounding the crushing area.

Main empirical dependences at crushing.

Dependence of resistance on the angle between the direction of the force and the direction of the wood fibers

R cm, a \u003d R cm, 0 / (1 + (R cm, 0 / R cm, 90 - 1) sin 3 a

Dependence of resistance on the length of the crush area

R cm, L = R cm (1 + 8 / (L cm + 1.2);[cm]

chipping. The work of wood for shearing (shear) is characterized by low strength and brittle fracture. In a "pure" form, chipping practically does not occur. Usually this type of stress state is combined with others (tension and compression across the fibers).

There are two types of chipping: one-sided chipping and two-sided chipping. In the first case, the strength is less, since the degree of uneven distribution of stresses is higher. In the calculations, a uniform distribution of stresses along the length of the shear area is conditionally assumed. Therefore, the concept of "average shear resistance" is introduced.

R sk,av = R sk,av / (1+ bL/e)

The formula reflects the physical essence of the shearing phenomenon: coefficient b takes into account the type of shearing, and the L/e ratio takes into account the effect of normal stresses accompanying shearing. R sk, sr- resistance to chipping with a uniform distribution of shear stresses.

The dependence of chipping resistance on the angle between the direction of the force and the direction of the wood fibers has the form:

R sc, a = R sc, 0 / (1 + (R sc, 0 / R sc, 90 - 1) sin 3 a

| Purpose of connections |

In designs manufactured in the factory |

In structures manufactured using lightweight means of mechanization. |

|

|

dried lumber |

from beams and boards |

from local roundwood |

|

| Rallying | With waterproof adhesive | On oak or birch Derevyagin plates; on nails and dowel pins made of round steel, of plastics | On pads, bolts, brackets |

| Building | |||

| In a tight joint |

frontal stop |

||

| In a stretched joint | Serrated joint on waterproof glue | Wooden slips and spacers on dowels made of round steel, on bolts, nails | Wooden plates on round steel dowels, bolted |

| Overlays with glued washers | Overlays with washers on deaf dowels and screws | Steel overlays with washers on deaf dowels and capercaillie | |

| Nodal adjunctions | |||

| Compressed rods | Frontal and three-frontal emphasis | Frontal notch; frontal and three-frontal emphasis | |

| tension rods | Steel bands or clamps through linings and gaskets on glue or dowels and bolts | Steel bands or clamps through linings and gaskets on nails or dowels and bolts | Steel strands or clamps through the lining on the dowels and bolts; cross profile brackets |

| Rods that perceive alternating forces | Center bolt through glue washers | Pins, cross profile pins, nails | Nagels, pins of a cross profile |

| Center bolt, through claw washers, washers on blind dowels, screws, cross pins or nails | Center bolt through washers on deaf dowels, capercaillie or cross profile pins | ||

The main types of connections (when rallying)

1. Connections on cuts working without special working connections. Connections are thrustless; only auxiliary cross ties are required (obsolete type of rallying)

|

|

| Connection diagram on cuts | |

| The main area of application of cuttings is the nodal connections in block and log trusses, including in the support nodes of the junction of the compressed upper chord to the stretched lower chord.

Elements of wooden structures (d.c.) connected by a notch must be fastened with auxiliary connections - bolts, clamps, brackets, etc., which should be calculated mainly for mounting loads |

|

|

|

2. Connections doweled working mainly for compression(c), similar to the compressed braces of the truss (c). Spacer Q w is perceived by working cross-links (p) - bolts, clamps, etc., working on stretching similar to stretched truss posts (p)

|

|

|

Dowel connection diagram |

3. Connections on dowels working mainly for bend(and), similarly to the racks (and) of a diagonal truss. Connections are non-expansion, only auxiliary cross braces are required

4. Connections on glue working mainly on shift(τ), similar to a weld in metal beams. Cross-linking is usually provided by the adhesive line itself.

Width Connections

When joining narrow boards, shields of the required dimensions are obtained.

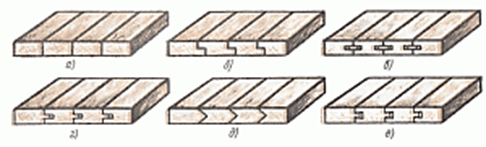

There are several ways to connect.

1)Connection on a smooth fugue;

With this connection method, each rail or board is called a plot, and the seam that is formed as a result of the connection is called a fugue. The quality of the jointing is indicated by the absence of gaps between the joints of the edges of adjacent plots.

2)Rail connection;

Along the edges of the plots, grooves are selected and inserted into their rails, fastening the plots together. The thickness of the lath and the width of the groove should not exceed 1/3 of the thickness of the board.

3) Connection in a quarter;

In fastened plots, quarters are selected along the entire length. In this case, the dimensions of the quarter, as a rule, do not exceed half the thickness of the plot.

3) Tongue and groove connection (rectangular and triangular);

This type of connection provides the plot with a groove on one side and a ridge on the other. The comb can be either rectangular or triangular, but the latter is rarely used because its strength is slightly worse. The tongue and groove connection is quite popular and is often used by parquet manufacturers. The disadvantage of such a connection is considered to be less economical, since more boards are used.

4) Dovetail connection;

This type of fastening is a bit similar to the previous one, only the comb has a trapezoidal shape. Well, hence the name.

Connection of boards into shields: a - on a smooth fugue, b - in a quarter, c - on a rail, d - in a groove and a rectangular comb, e - in a groove and a triangular comb, e - in a dovetail

Also, when assembling the shields, dowels, tips in the groove and a comb with the rail pasted into the end are used. Among the glued rails, there are triangular, rectangular and glued ones, and when using the dowel, the dovetail groove is mainly chosen. All this is necessary for reliable fastening of the shield.

Shields: a - with dowels, 6 - with a tip in the groove and comb, c - with a glued rail in the end, d - with a glued triangular rail, e - with a glued triangular rail.

Length connection

Among the popular types of connections along the length can be distinguished: end-to-end, on the "mustache", in the groove and comb, on the toothed adhesive connection, in a quarter and on the rail. The most popular gear connection, because it has the best strength.

The connection of the bars along the length: a - end-to-end, b - in the groove and ridge, c - on the mustache, d, d - on the toothed adhesive connection, e - in a quarter, g - on the rail

There is also splicing, when longer segments are joined together. This can happen in several ways. For example, half a tree, oblique cut, oblique and straight overhead lock, oblique and straight tension lock and end-to-end. When choosing half-wood splicing, the required joint length should be 2 or 2.5 times the thickness of the timber. For greater reliability, dowels are used, for example, this can be found in the construction of cobbled houses.

When using an oblique cut with end trimming, the dimensions are 2.5 - 3 of the thickness of the beam and are also fastened with dowels.

The connection with a straight or oblique overhead lock is used in structures in which tensile forces are present. A straight overhead lock is located on a support, and an oblique one can be placed at the supports.

If you decide to use a bevel cut with end trimming, then the connection should have 2.5 or 3 bar thicknesses. In this case, the same dowels are used.

When docking with a straight or oblique tension lock, you don’t have to worry about strength, but such a connection is difficult to manufacture, and when the wood dries out, the wedges weaken, so this connection method is not suitable for serious structures.

Butt splicing is when the two ends of the beam are placed on a support and securely connected with staples.

Splicing: a - half a tree, b - oblique cut, c - straight overhead lock, d - oblique overhead lock, d - straight tension lock, e - oblique tension lock, g - end-to-end

The connection of beams or logs can be found in the construction of walls or in the upper or lower trim in frame houses. The main types of compounds are half a tree, half-paw, spiked and corner frying pan.

A half-tree cut is considered to be a cutting or cutting of half the thickness at the ends of the bars, after which they are connected at an angle of 90 degrees.

The half-lap connection is formed when cutting at the ends of the bars of inclined planes, due to which the bars are tightly connected. The slope size is determined by the formula.

Cutting with a corner frying pan is very similar to cutting in half a tree, but the distinguishing feature is that with such a connection one of the bars loses a small part in width.

Building

The extension of beams and logs is the connection of elements in height, which is often used in the construction of poles or a match.

There are several types of extensions:

1) butt with a hidden spike;

2) end-to-end with a through comb;

3) half-wood with bolting;

4)half a tree with fastening with clamps;

5) half-tree with fastening with strip steel;

6) oblique cut with fastening with clamps;

7) butt with overlays;

8) bolting;

The length of the joints is usually 2-3 of the thickness of the joined beams or 2-3 of the diameter of the logs.

Connection of logs during extension: a - end-to-end with a hidden spike, b - end-to-end with a through ridge, c - half-tree with fastening with bolts, d - half-tree with fastening with strip steel, e - half-tree with fastening with clamps, e - oblique cut with fastening with clamps, g - end-to-end with overlays and fastening by bolts

spike connection

When spike knitting bars, a spike is cut on one, and an eye or nest is made on the other. Spike knitting of bars is often used to create joinery, doors, windows or transoms. All connections are made with glue. You can use not only one, but two or more spikes. The more spikes, the larger the bonding area. This type of connection can be divided into corner end, corner middle and corner box.

At the corner end connection, an open through spike is used (one, two or three), a spike with a dark through and blind, plug-in dowels. Angular middle connections can be found on the doors. Angled middle and end can additionally use nails, screws, dowels or bolts.

Corner spike connections: a - open through single spike UK-1, b - open through double spike UK-2, c - open through triple spike UK-3, d - blind spike with semi-darkness UK-4, e - through spike with semi-darkness UK-5; blind on the mustache with a plug-in flat stud UK-10, l - through on the mustache with a plug-in flat stud UK-11

Angled middle joints on the spike: a - blind type US-1, b through US-2, c - double through US-3, d - blind into the groove and crest US-4, e - blind into the groove US-5, e - blind on round dowels US-6

In addition to processing solid pieces of wood, it is often necessary to connect wooden parts into knots and structures. Connections of elements of wooden structures are called landings. Joints in the construction of wooden parts are defined by five types of fits: tense, tight, sliding, loose and very loose fit.

Knots - these are parts of structures at the junction of parts. Connections of wooden structures are divided into types: end, side, corner T-shaped, cross-shaped, corner L-shaped and box corner connections.

Joiner connections have more than 200 options. Only connections used in practice by joiners and carpenters are considered here.

End connection (building) - the connection of parts along the length, when one element is a continuation of another. Such joints are smooth, jagged with spikes. Additionally, they are fixed with glue, screws, overlays. Horizontal end connections withstand compressive, tensile and bending loads (fig. 1 - 5). Lumber is increased in length, forming vertical and horizontal jagged joints (wedge lock) at the ends (Fig. 6). Such joints do not need to be under pressure during the entire bonding process, since significant frictional forces act here. Gear joints of sawn timber, made by milling, meet the first class of accuracy.

Joints of wooden structures must be made carefully, in accordance with the three accuracy classes. The first class is intended for high quality measuring tools, the second class is for furniture production, and the third is for building parts, agricultural implements and containers. The lateral connection of several boards or battens with an edge is called rallying (Fig. 7). Such connections are used in the construction of floors, gates, carpentry doors, etc. Plank, rack panels are additionally reinforced with crossbars and tips. When sheathing ceilings, walls, the upper boards overlap the lower ones by 1/5 - 1/4 of the width. The outer walls are sheathed with horizontally laid overlapping boards (Fig. 7, g). The upper board overlaps the lower one by 1/5 - 1/4 of the width, which ensures the removal of atmospheric precipitation. The connection of the end of the part with the middle part of the other forms a T-shaped connection of the parts. Such compounds have a large number of variants, two of which are shown in Fig. 8. These connections (knitting) are used when pairing the log of ceilings and partitions with the harness of the house. The connection of parts at a right or oblique angle is called a cruciform connection. Such a connection has one or two grooves (Fig. 3.9). Cross-shaped connections are used in the construction of roofs and trusses.

|

| Rice. 1. End connections of the bars, resisting compression: a - with a straight half-wood overlay; b - with an oblique overlay (on the "mustache"); c - with a straight half-wood overlay with a joint in an obtuse angle; g - with an oblique overlay with a joint into a spike. |

|

| Rice. 2. End connections of the bars (extension), resisting stretching: a - in a straight overhead lock; b - in an oblique laid on lock; c - with a straight overlay half a tree with a joint in an oblique spike (in a dovetail). |

|

| Rice. 3. End connections of beams that resist bending: a - with a straight half-wood overlay with an oblique joint; b - with a straight overlay half a tree with a stepped joint; in - in an oblique laid on lock with wedges and with a joint in a thorn. |

|

| Rice. 4. Splicing with a notch reinforced with wedges and bolts. |

|

| Rice. 5. End connections of the bars, working in compression: a - end-to-end with a hidden hollowed-out spike; b - end-to-end with a hidden plug-in spike; c - with a straight overlay half a tree (the connection can be reinforced with bolts); d-with a straight overlay half a tree with wire fastening; e - with a straight overlay half a tree with fastening with metal clips (clamps); e - with an oblique overlay (on the "mustache") with fastening with metal clips; g - with an oblique overlay and fastening with bolts; h - marking the oblique lining; and - end-to-end with a secret tetrahedral spike. |

|

| Rice. Fig. 6. End extensions of the milling scheme for end gluing of workpieces: a - vertical (along the width of the part), toothed (wedge-shaped) connection; b - horizontal (through the thickness of the part), gear (wedge-shaped) connection; c - gear joint milling; g - sawing out a gear connection; e - milling of a gear connection; e - end connection and gluing. |

|

| Rice. 7. Rallying boards: a - for a smooth fugue; b - on the plug-in rail; in - in a quarter; d, e, f - into a groove and a crest (with various forms of a groove and a crest); g - overlap; h - with a tip in the groove; and - with a tip in a quarter; to - with overlap. |

|

| Rice. 8. T-shaped joints of bars: a - with a hidden oblique spike (in a paw or in a dovetail); b - with a straight stepped overlay. |

|

| Rice. 9. Cross connections of bars: a - with a straight overlay half a tree; b - with a direct overlay of incomplete overlap; c - with landing in one nest |

The connections of two parts with ends at a right angle are called angular. They have through and non-through spikes, open and in the dark, half-dark overlay, half-tree, etc. (Fig. 10). Corner joints (knitting) are used in window irregular blocks, in greenhouse frame joints, etc. The stud joint in the dark has a stud length of at least half the width of the connected part, and the groove depth is 2–3 mm more than the stud length. This is necessary so that the parts to be joined easily mate with each other, and after gluing, there is room for excess glue in the spike socket. For door frames, an angular tenon connection is used in the dark, and to increase the size of the connected surface, in a semi-darkness. A double or triple tenon increases the strength of the gusset. However, the strength of the connection is determined by the quality of its implementation. In furniture production, a variety of corner box joints are widely used (Fig. 11). Of these, the simplest is an open end-to-end spike connection. Before making such a connection, spikes are marked with an awl at one end of the board according to the drawing. By marking the side parts of the spike with a file with fine teeth, a cut is made. Every second cut of the spike is hollowed out with a chisel. For the accuracy of the connection, they first saw through and gouge out the sockets for the spikes in one piece. It is applied to the end of another part and crushed. Then they saw through, gouge and connect the parts, cleaning the connection with a planer, as shown in fig. eleven.

When connecting the parts to the "mustache" (at an angle of 45 °), the angular knitting is fixed with steel inserts, as shown in fig. 12. At the same time, make sure that one half of the insert or clamp is included in one part, and the other half is in the other. A wedge-shaped steel plate or ring is placed in the milled grooves of the parts to be joined.

The corners of frames and boxes are connected with a direct open through spike connection (Fig. 3.13, a, b, c). With increased quality requirements (thorns are not visible from the outside), corner knitting is performed by an oblique blind connection, a groove and a ridge, or an oblique connection to a rail, as shown in fig. 13, d, e, f, g and in fig. fourteen.

A box structure with horizontal or vertical transverse elements (shelves, partitions) is connected using corner T-shaped joints shown in fig. fifteen.

In connecting the elements of the upper belt of wooden trusses with the lower one, corner cuts are used. When mating the truss elements at an angle of 45 ° or less, one cut is made in the lower element (puff) (Fig. 16, a), at an angle of more than 45 ° - two cuts (Fig. 16.6). In both cases, the end cut (cut) is perpendicular to the direction of the acting forces.

Additionally, the nodes are fixed with a bolt with a washer and a nut, less often with brackets. The log walls of the house (log house) from horizontally laid logs in the corners are connected with a cut “in the paw”. It can be simple or with an additional spike (shank with a pit). The marking of the cut is performed as follows: the end of the log is hewn into a square, to the length of the side of the square (along the log), so that after processing a cube is obtained. The sides of the cube are divided into 8 equal parts. Then, 4/8 part is removed from one side from below and from above, and the remaining sides are performed, as shown in Fig. 17. Templates are used to speed up the marking and the accuracy of making cuts.

|

| Rice. 10. Corner end connections of blanks at a right angle: a - with a single opening through a spike; b - with a single through hidden spike (in the dark); in-with a single deaf (non-through) thorn in the dark; g - with a single through semi-secret spike (in semi-darkness); d - with a single deaf spike in semi-darkness; e - with a triple open through spike; g - in a straight overlay half a tree; h - in a through dovetail; and - in eyelets with undercutting. |

|

| Rice. 11. Box corner joints with straight through spikes: a - sawing tenon grooves; b - marking the spikes with an awl; in - connection of a thorn with a groove; g - processing by a planer of a corner joint. |

|

| Rice. 12. Corner end connections at a right angle, reinforced with metal inserts - buttons: a - 8-shaped insert; b- wedge-shaped plate; in rings. |

|

| Rice. 13. Box corner joints at a right angle: a - straight open through spikes; b - oblique open through spikes; in - open through dovetail spikes; g - groove on the plug-in rail end-to-end; d - in the groove and crest; e - on plug-in spikes; g - on spikes in a dovetail in semi-darkness. |

|

| Rice. 14. Oblique (on the "mustache") box connections at a right angle: a - oblique spikes in the dark; b - oblique connection on a plug-in rail; in - oblique connection on spikes in the dark; g - an oblique connection, reinforced with a trihedral rail on glue. |

|

| Rice. 15. Direct and oblique connections of blanks: a - on a double connection in an oblique groove and ridge; b - on a straight groove and comb; in - on a trihedral groove and a crest; g - on a straight groove and a comb in the dark; d - on straight through spikes; e - on round plug-in spikes in the dark; g - on a spike in a dovetail; h - on the groove and the crest, reinforced with nails. |

|

| Rice. 16. Nodes in farm elements. |

|

| Rice. 17. Conjugation of the logs of the walls of the log house: a - a simple paw; b - a paw with a wind spike; c - paw markings; 1 - wind spike (pit) |

All photos from the article

Sometimes, when carrying out construction and other work using wood, it is required to make elements longer or wider, and very few people know how to do this correctly. That is why we will consider how to splice the board yourself and what methods and techniques exist. It is important to choose the option that is best suited in a given situation and will require minimal time and money.

Basic workflow requirements

Before we begin to consider specific options for carrying out work, it is necessary to understand what factors are observed to ensure that the result that is expected is obtained:

| Material quality | Everything is simple here: it is impossible to make durable structures out of low-quality wood, especially when it comes to joints, if they have knots, damage by woodworms, mold and other problems, then there can be no question of any reliability and durability. Choose the best elements so as not to waste your energy and money in vain |

| Humidity | Another most important parameter that should always be taken into account. Only dry elements are suitable for work, since high humidity, firstly, reduces strength, secondly, reduces the adhesion of the adhesive composition when it is used, and thirdly, after completion of work, no one will guarantee that in a week or a month the structure will not lead or it will not crack |

| Connection loads | It is on this indicator that the choice of one or another connection option largely depends, the greater the load, the higher the requirements for the quality of the interface and the more difficult the process. Therefore, decide in advance which option will be used in order to guarantee a high result. |

| Using a quality tool | A lot also depends on this, especially when it comes to complex options, when the connection is cut with special tools. They must provide maximum cutting quality and maximum docking accuracy, since reliability largely depends on this. |

Important!

Remember one simple rule that experts always use: to obtain the best result, it is necessary that the parameters of the connected elements be similar, in other words, one type of wood should be used.

Work options

All events of this kind can be divided into two large groups - rallying boards in width and length, we will consider them separately and tell you which methods are the most popular and how to implement them correctly.

Width connection

Of course, the simplest solution would be a shield splicing option, so we will start with it, first we will present a diagram of the main options, and below we will describe them in detail:

- The first method involves cutting a cavity with a milling machine, which has a trapezoidal shape and allows the use of a key as a retainer.. Reliability can be called a plus of this solution, and a minus is the need for a milling machine or the presence of a manual milling cutter for work, you can’t get by with a hand tool;

- Rallying using an end bar, which is connected to the ends of the board using the tongue-and-groove method, is used for elements of small length, since this option provides high reliability of precisely small structures. Again, you will need to work. With his help, it will be carried out quickly and efficiently;

- You can make a cutout on the end, fit the rail under it and put it on wood glue, this is also a rather interesting option that is suitable for small structures;

- The last two options involve gluing a triangular rail, only one of them cuts into the end, and the second option involves cutting the end at an angle, you need to choose what is best suited in a given situation.

But if you want to connect the board more securely, then one of the following methods will do:

- The second solution is the connection into the so-called minithorn, this is a very durable and reliable option, but for work you will need a special cutter, the price of which is high, so this method is chosen by those who often have to splice elements;

- If the elements are connected along the length not in one, but in two or more layers, then you can use the end-to-end option, such a connection of boards along the length is well suited for multilayer systems, in the figure it is under the letter A;

- The traditional groove-ridge option is often used, here it is important to ensure the optimal connection configuration, so the width of the groove and, accordingly, the tongue should not be more than a third of the total thickness of the board, it is important to cut very accurately so that the elements match perfectly, this will significantly increase the strength of the connection;

Important!

When working, a milling cutter is most often used, but the cutters can have a different configuration, you should monitor the condition of their cutting edges and sharpen or replace them in a timely manner, since the quality of the connection largely depends on the cleanliness of the processing.

- You can use the option of cutting at an angle, it is well suited where special strength is not required, but you need to connect elements that can be used for finishing, etc .;

- The triangular thorn-groove in many respects resembles the usual one, only the configuration of the ends differs. It is also important here that the elements fit perfectly with each other, as this will ensure both the accuracy of the pairing and its maximum reliability;

- A quarter connection is simple - cuts are made for half the thickness, the length of the protrusions should not greatly exceed the thickness, the elements are lubricated with glue and compressed until the composition dries, this is a standard procedure for almost all options;

- The last type is key rallying, it does not differ from the above option when working in width, the requirements are the same.

Conclusion

Correctly and reliably connecting the board means ensuring its maximum strength, it is important to follow all the recommendations and use only high-quality materials. The video in this article will show some of the options for carrying out the work clearly, and if you have questions or an addition, unsubscribe in the comments.

All photos from the article

In this article, we will review what options are available for joining wood products. And there are a great many such methods, from a simple butt joint to the most complex dovetail joint. It is important to remember that not all of them can be done on your own, but the information below will definitely not be superfluous.

Reliable hitch - a guarantee of strength and reliability for any design

Listing the available options

All of them are distinguished by their strength and complexity, for example, the cabinet body is assembled with a seam or butt joint, less often they use a “groove” or “moustache” combination. But for the manufacture of a door frame or panel, the skill of a spike connection is useful.

The following are ways to connect wooden parts.

Joining parts "butt"

Butt alignment is called fixing the edges. For this, fasteners and glue are usually used. But the butt joint is not very reliable, so it should be strengthened, which is not so difficult to do.

It is desirable to strengthen the butt fastener with a metal fastener: corners and self-tapping screws

This method is usually used when assembling the front frame of a cabinet, where strength is not important, since the frame parts are securely attached to the cabinet itself. Butt jointing of wooden structures is usually reinforced with lamellas or dowels, which are able to combine individual parts during gluing.

Fastening parts "in the mustache"

This combination has some differences from the previous one. When gluing the surface, the parts are beveled at an angle of 45 ° with respect to the axis. The connection of wooden parts "with a mustache" must also be strengthened with the help of additional fasteners.

Note! Typically, this method of combining is used when it is necessary to connect two pieces of molding in the corner.

Strengthening the connection of wood parts

As mentioned above, you can strengthen with the help of ordinary wooden dowels. Nagel fortifications are usually made with the help of two dowels, glued into one and the other end of the crossbar, into vertical posts, into their corresponding sockets. There is a specific instruction for making such connections:

We mark nests for dowels:

- For a clear markup, it is necessary to attach the parts to be fastened to each other.

- Draw a line with a pencil, marking the places for the dowels.